Products

Our catalogue

Over time, we have been able to meet the needs of its target market thanks to targeted technological investments in rubber moulding, such as high-precision injection and compression presses, to optimise the production of all types of items. These investments have enabled the company to improve production efficiency, reduce waste and guarantee repeatability across different production batches.

Today, we offer a wide and versatile catalogue that includes both standard and customised rubber products, designed to meet the specific technical requirements of each industrial sector. Whether it’s for sealing, vibration damping, or protection, our components are engineered to ensure high performance and long-term reliability.

We supply products for sectors such as automotive, food processing, pharmaceuticals, construction, HVAC, and more. Each item is made using carefully selected raw materials and is developed in-house by our technical team, which has decades of experience in rubber formulation and design.

Termogomma continues to stand out for its flexibility and reliability, offering quick lead times even for small production volumes, and guaranteeing impeccable product quality through strict in-line controls and advanced testing systems. Our catalogue reflects a combination of innovation, technical expertise, and constant commitment to customer satisfaction.

To gather more information about our components, check out the ATP Group’s website as well.

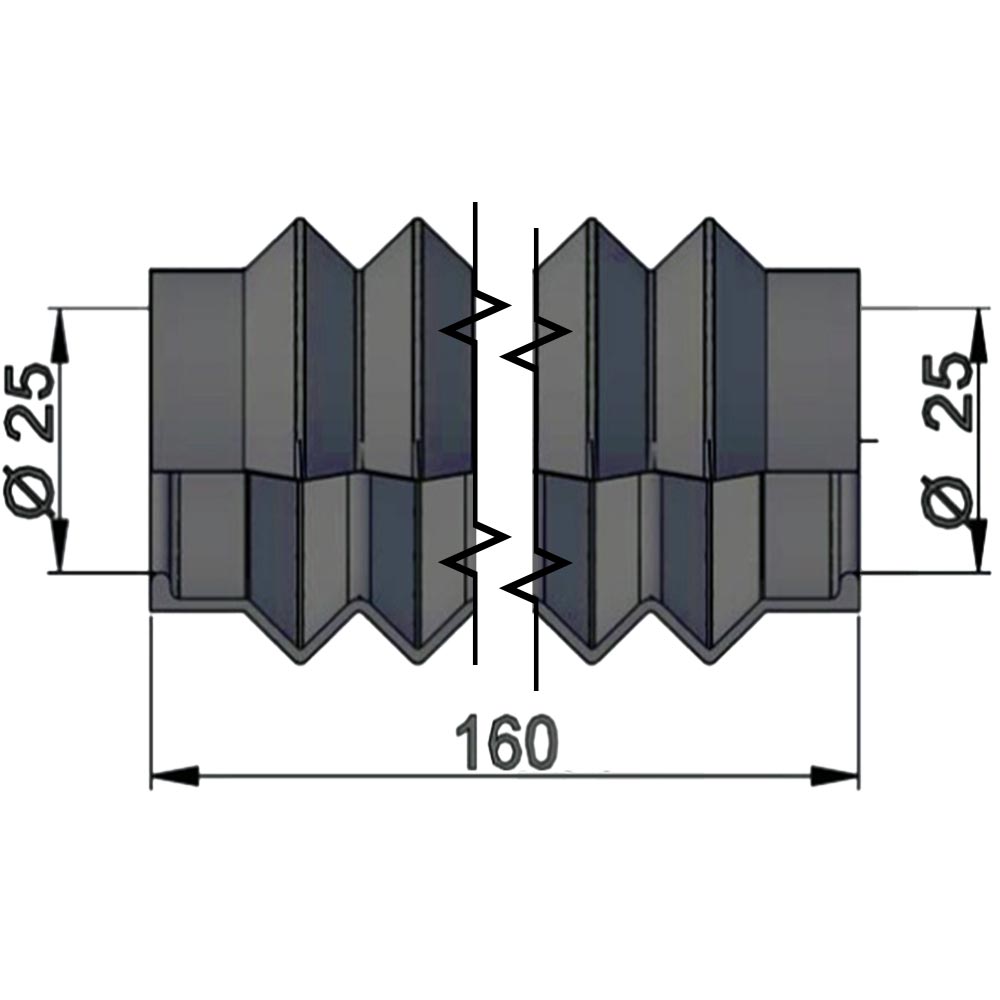

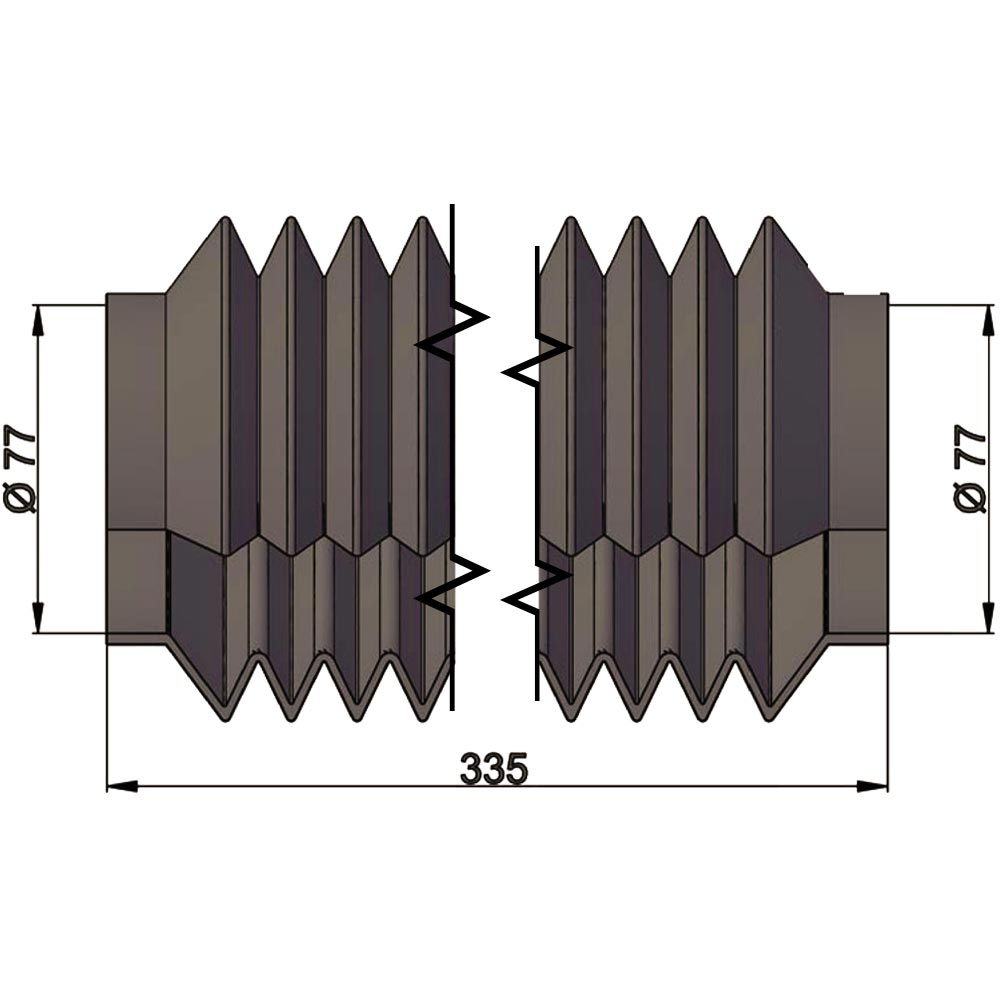

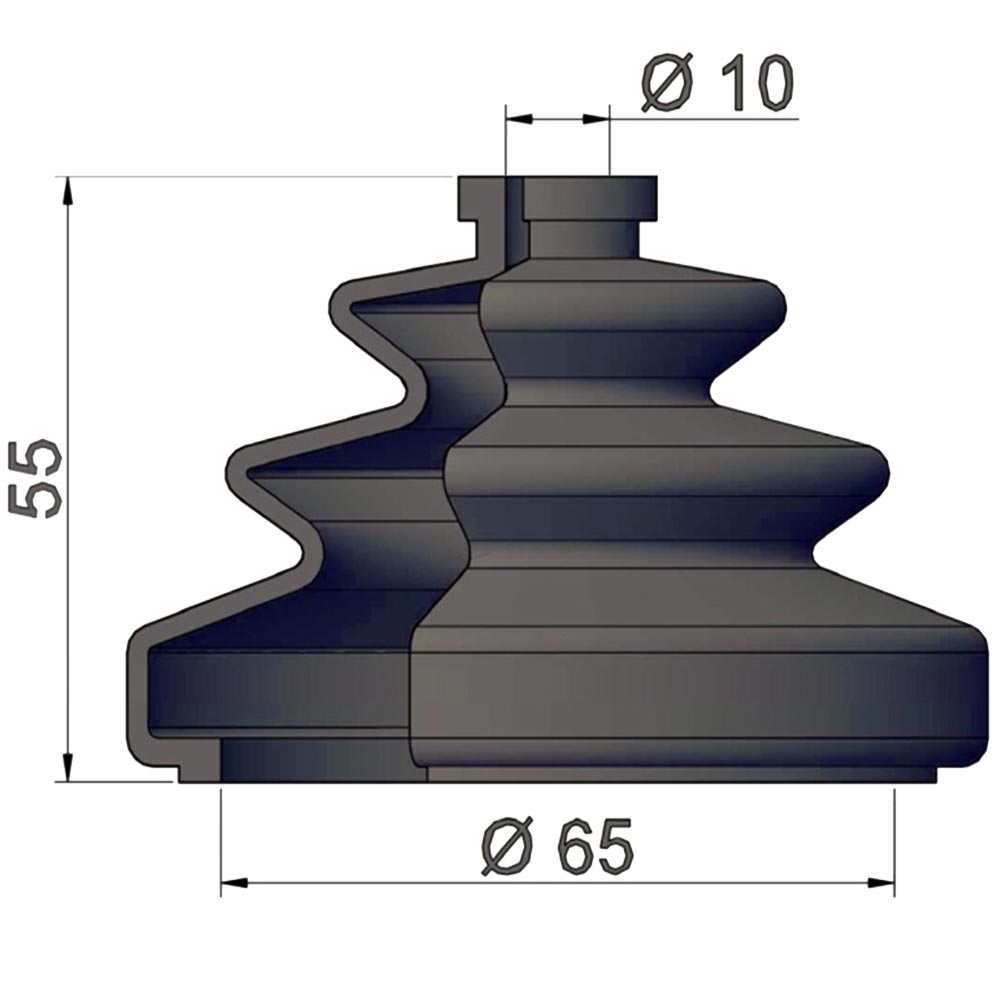

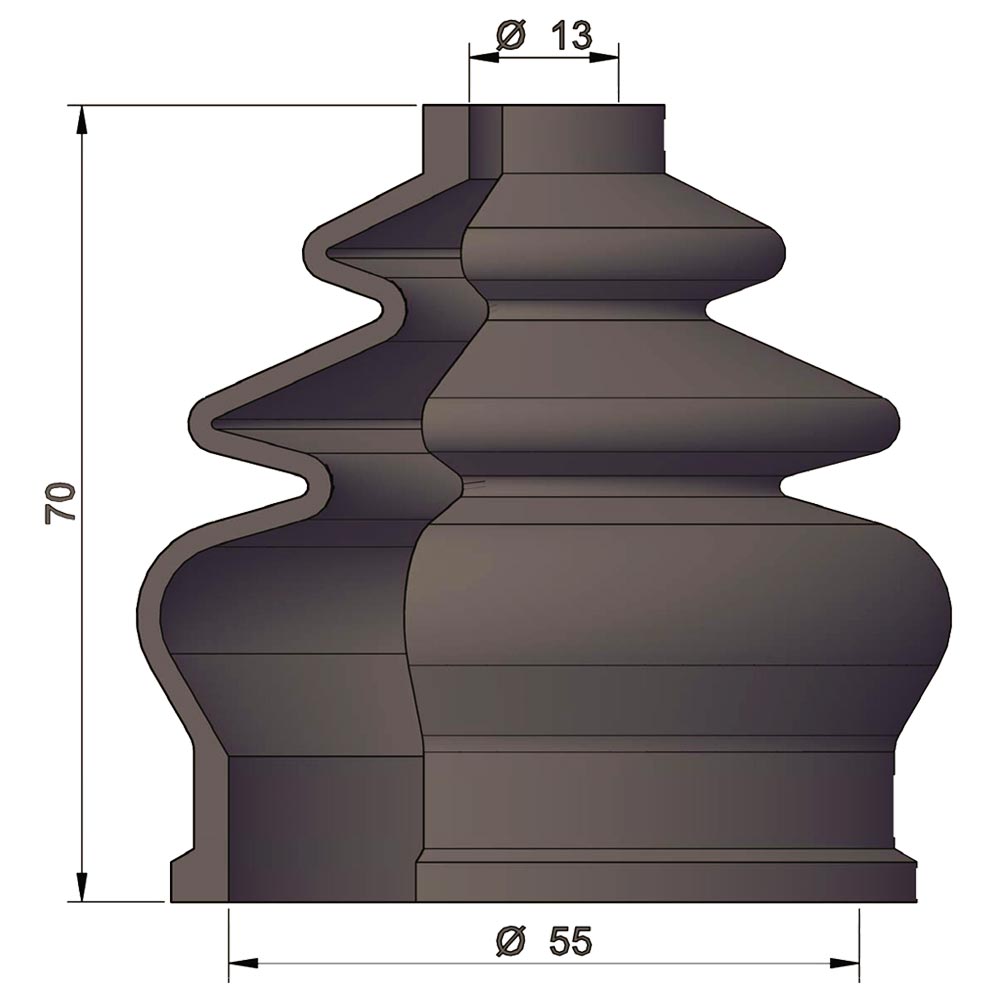

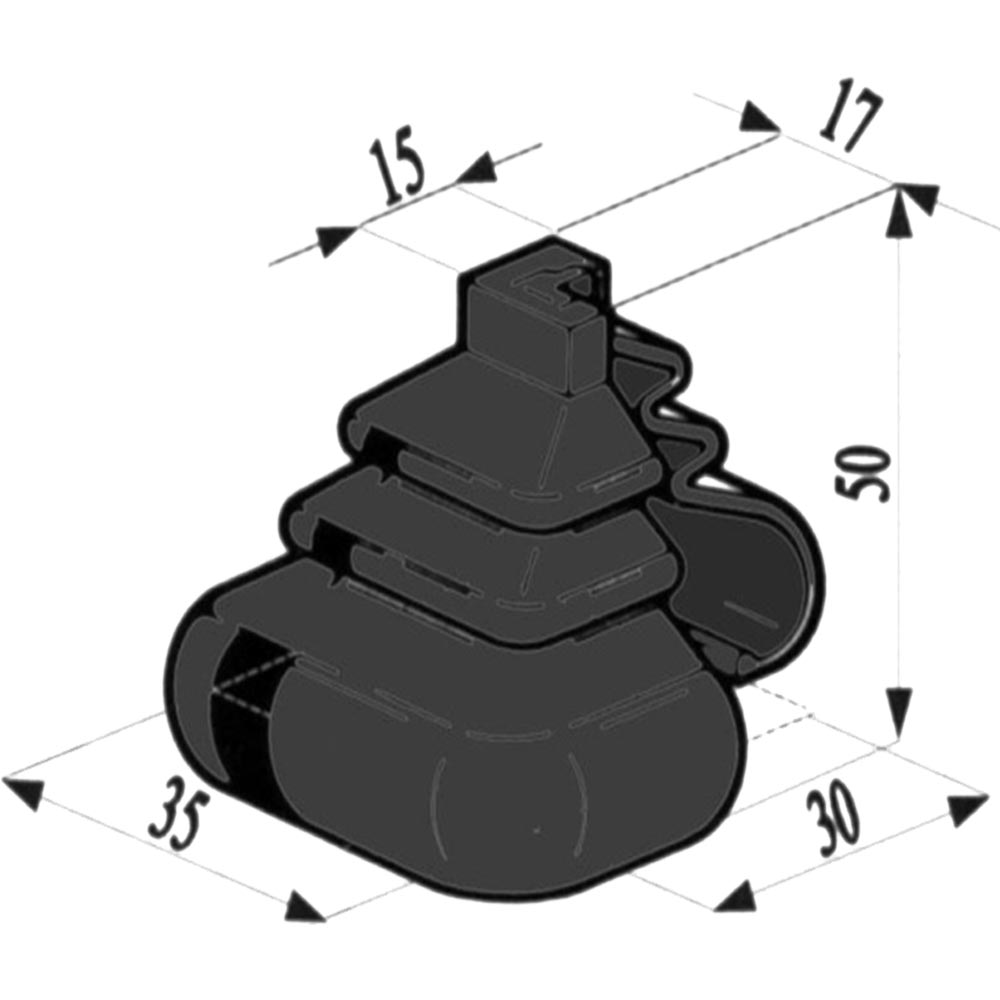

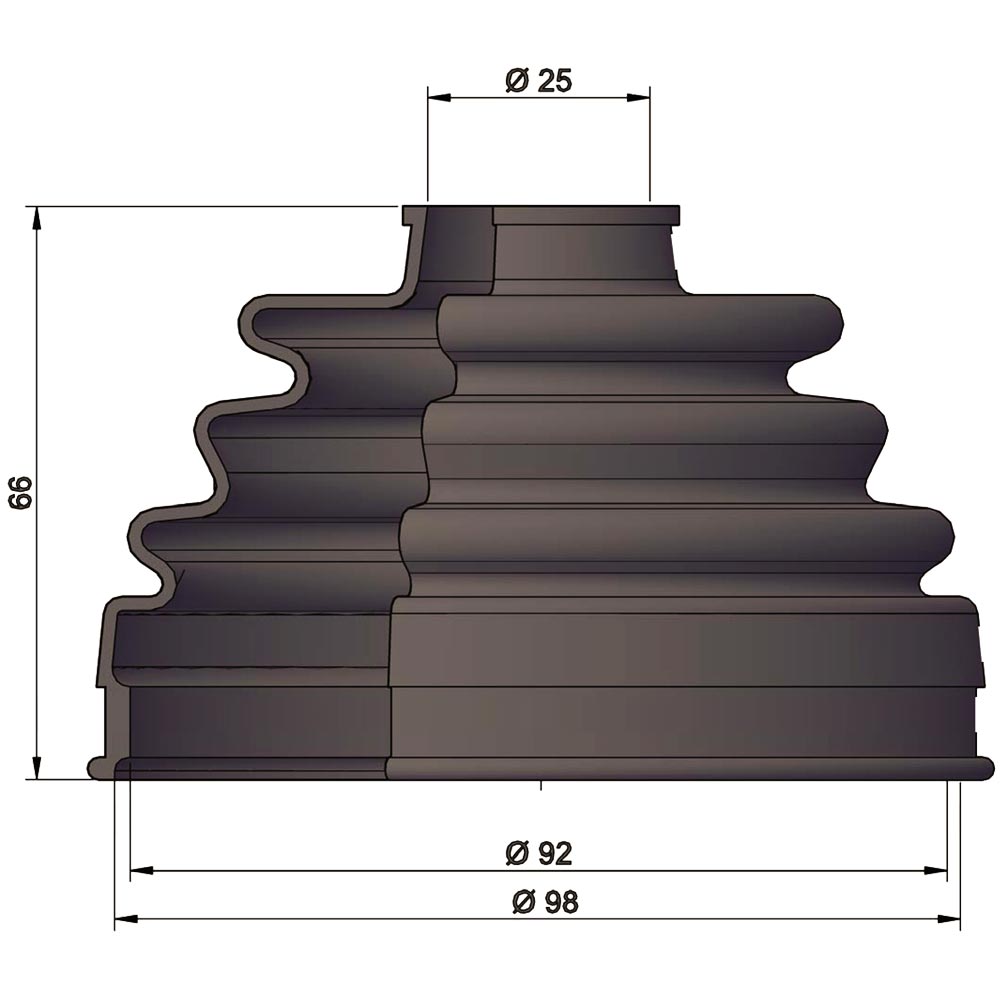

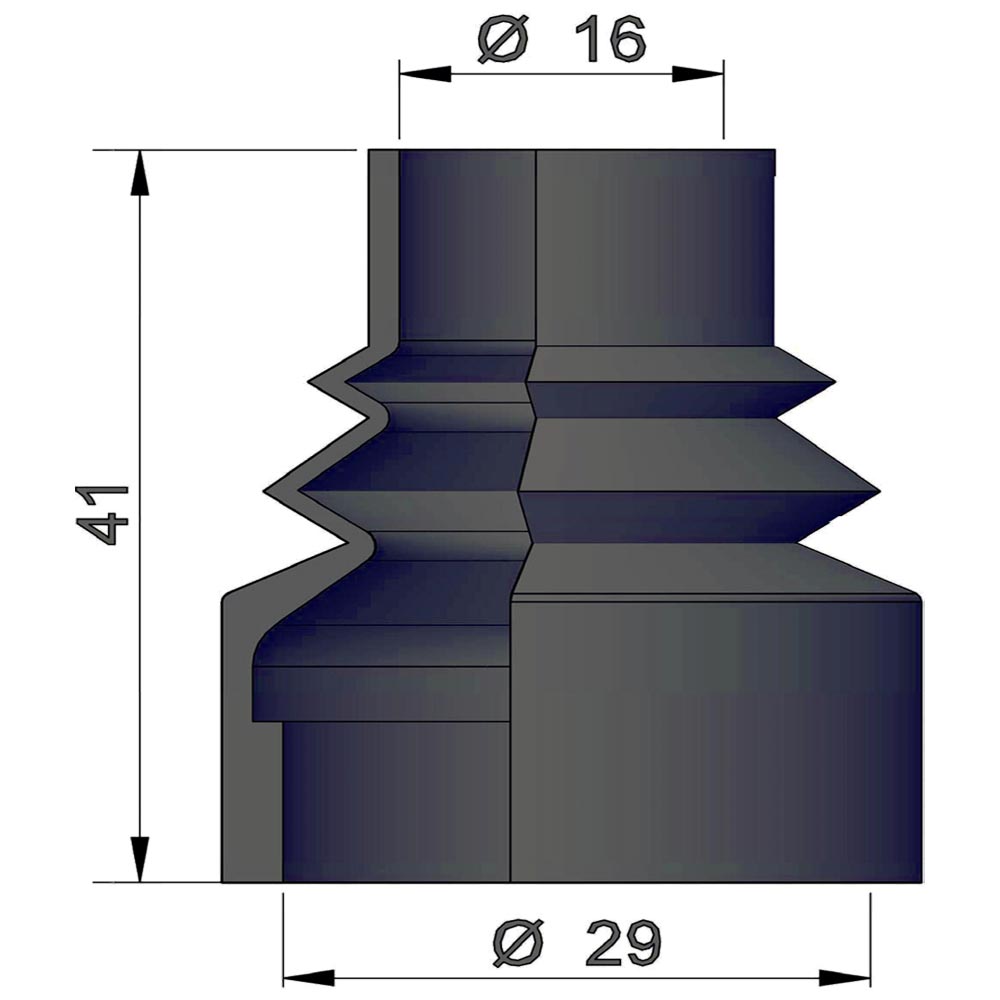

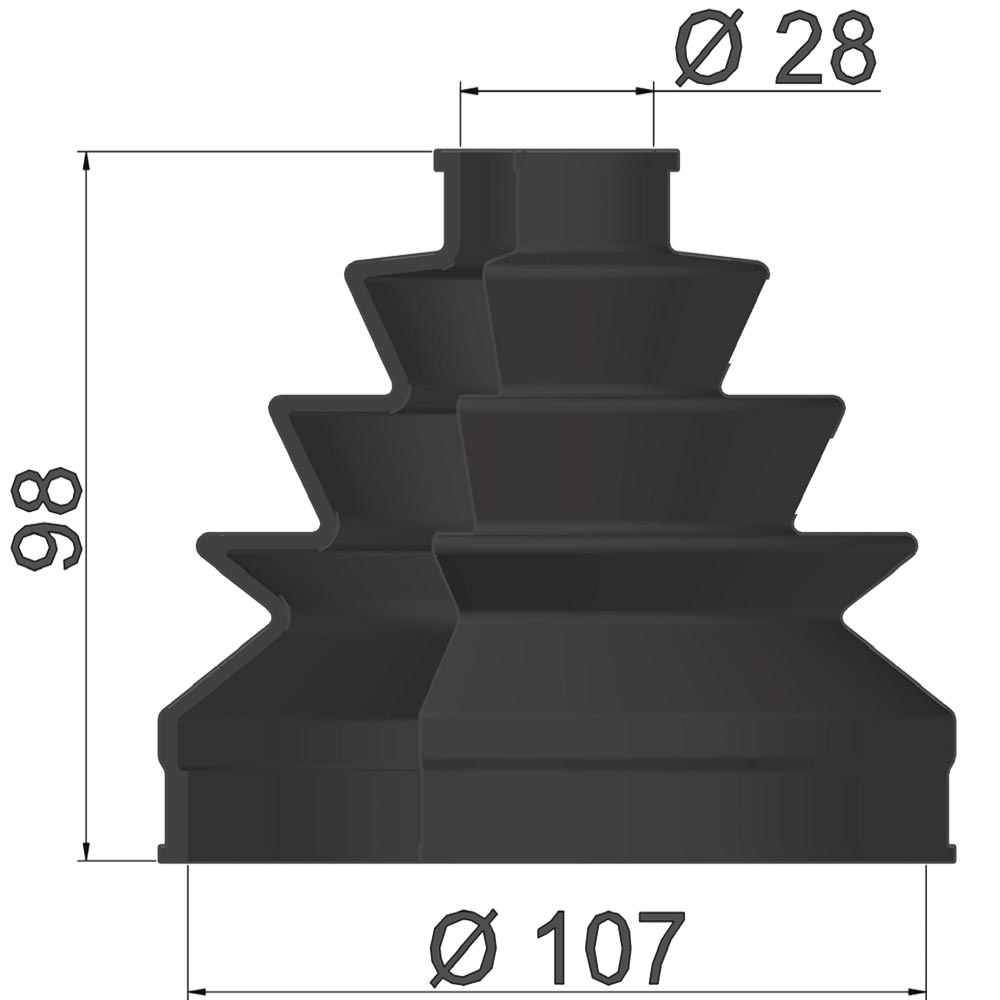

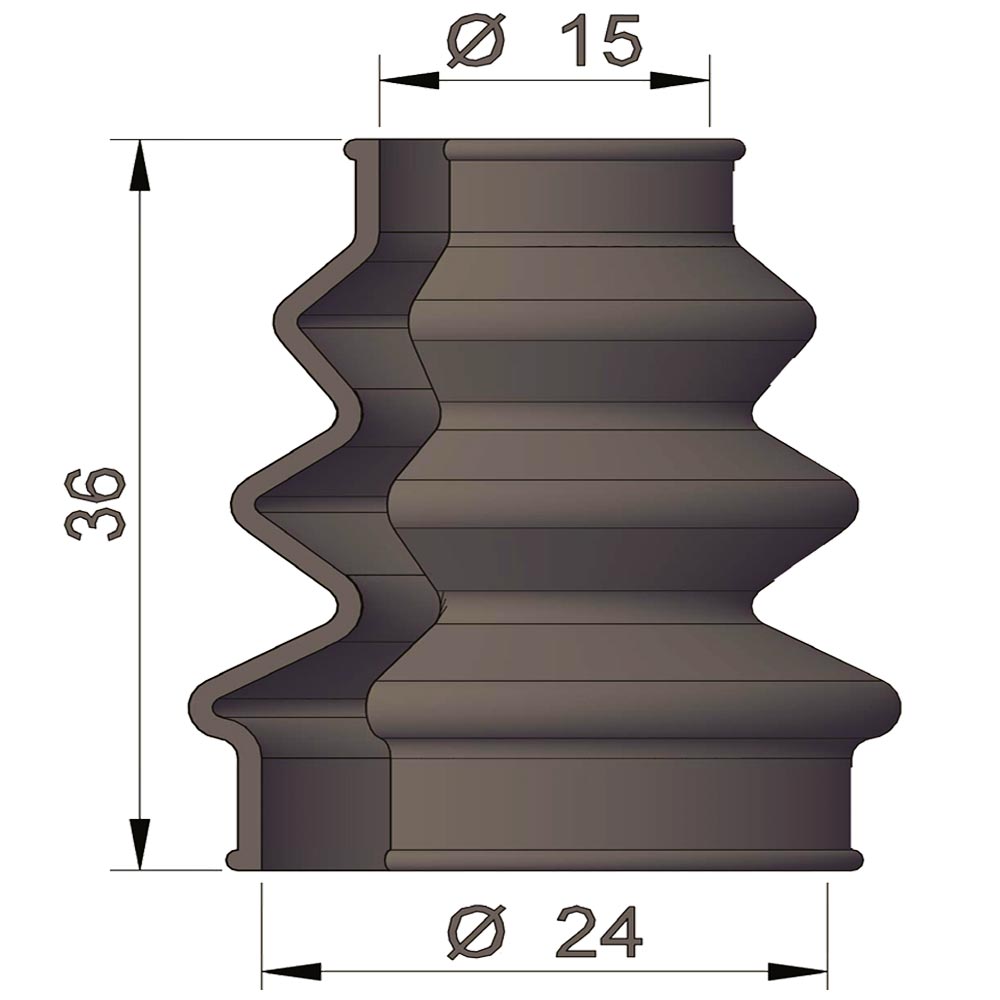

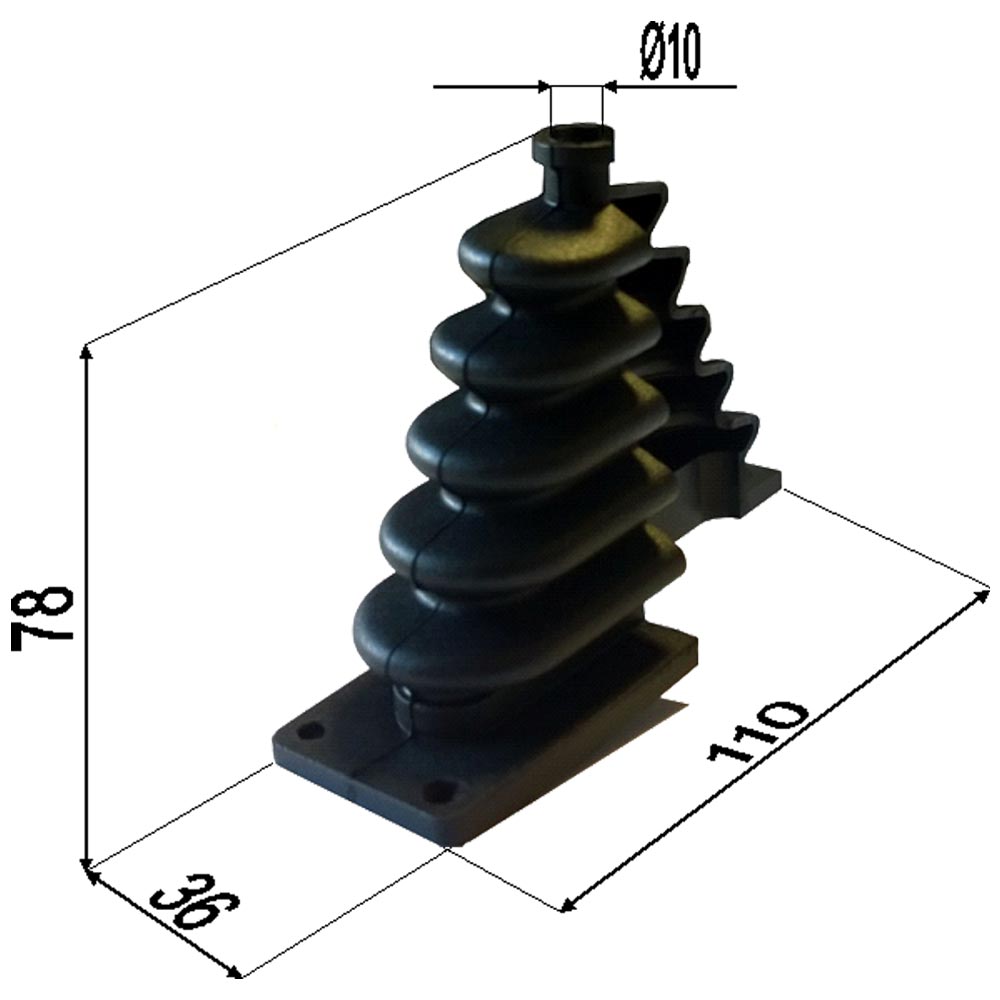

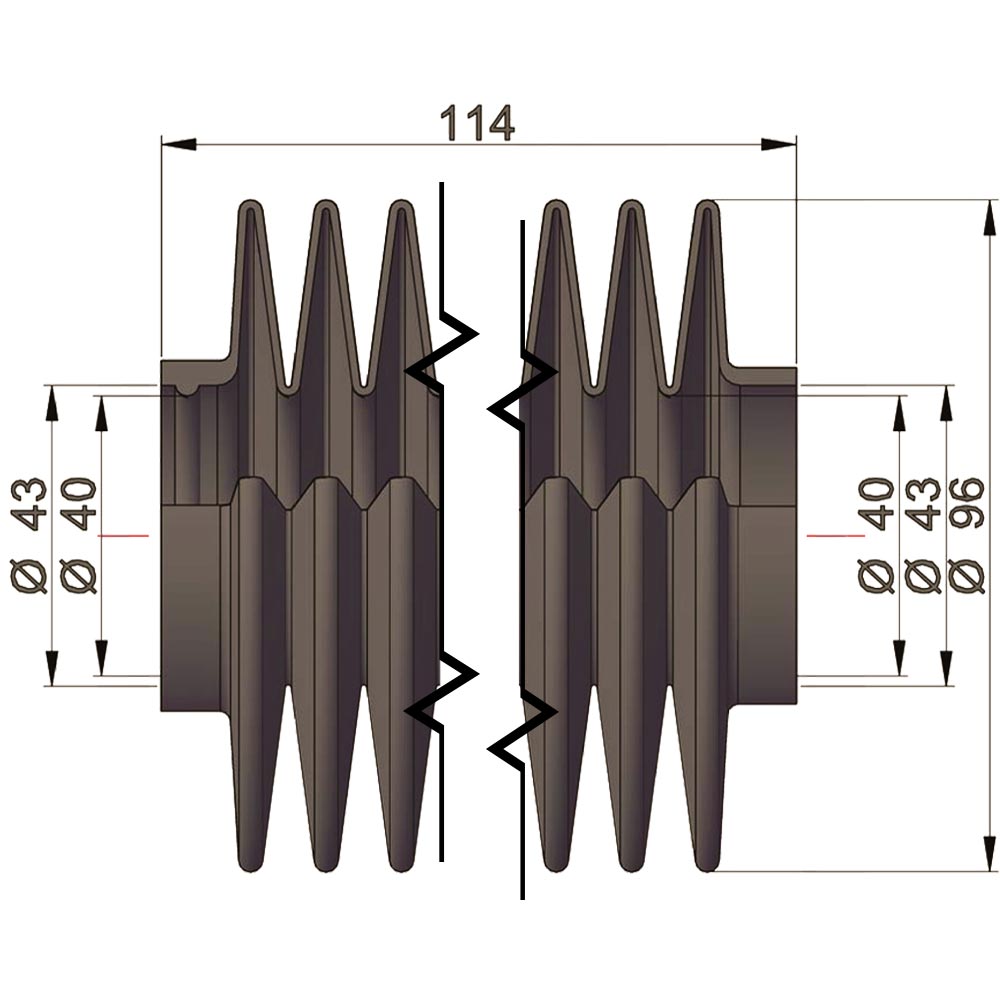

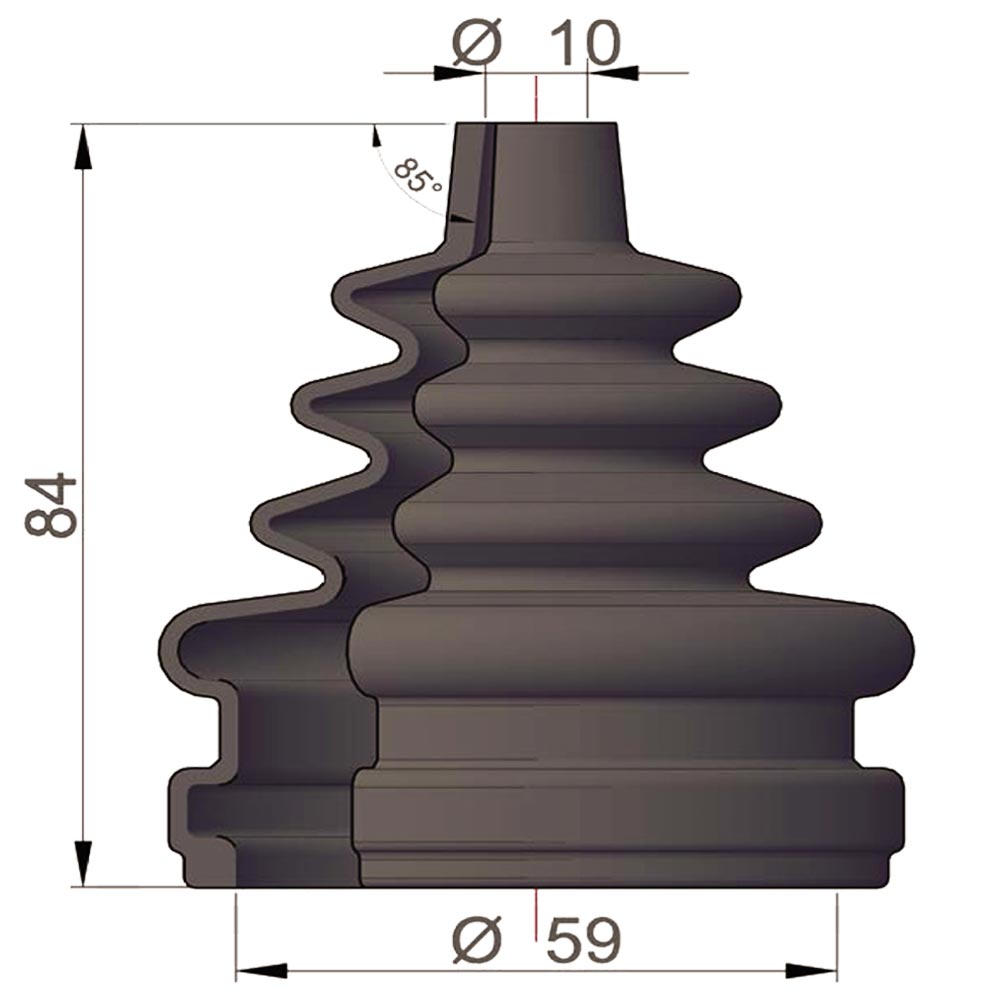

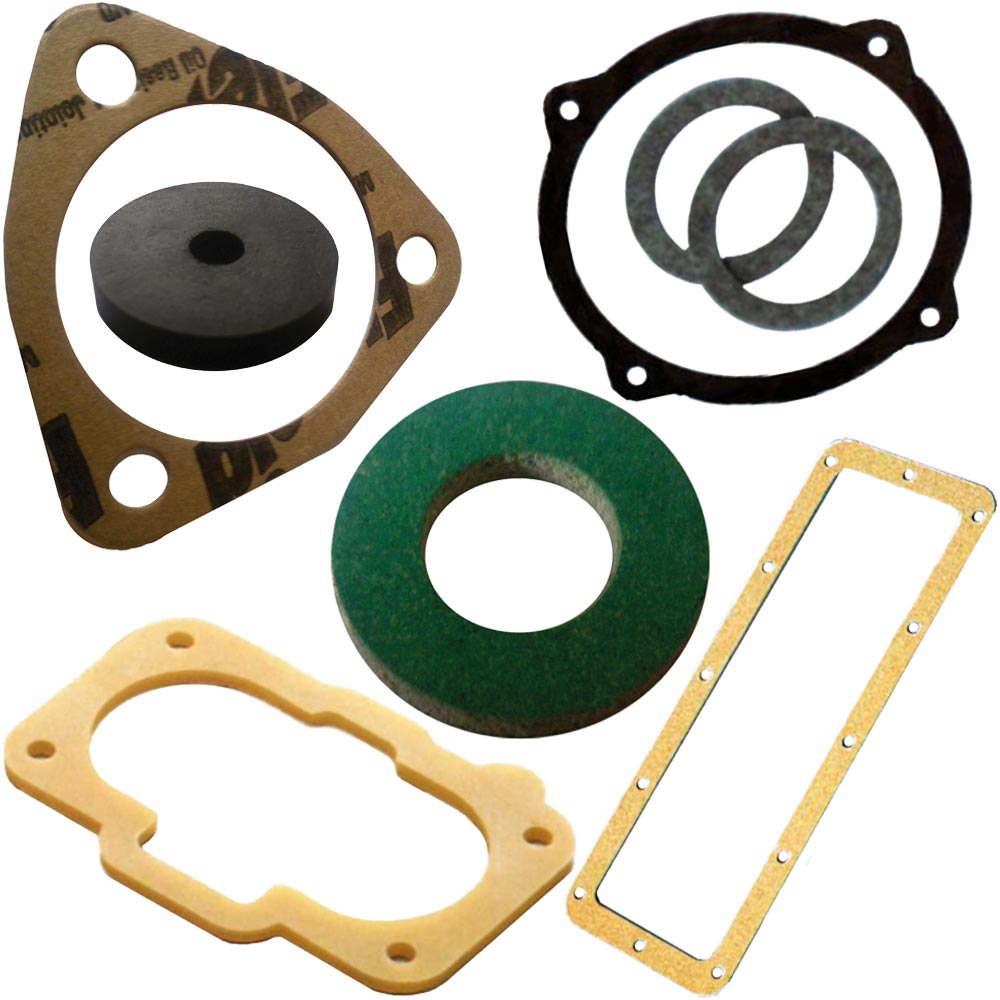

Thanks to their flexibility, elasticity and practicality, these products are designed to withstand various forms of mechanical stress. They are widely used across multiple industrial sectors for their durability and adaptability in demanding environments. Termogomma manufactures rubber-based items such as gaskets, bellows, fairleads, grips, membranes and tie rods, offering both standard and customised solutions to suit any technical requirement. All components are carefully developed to meet precise dimensional tolerances and guarantee consistent performance under pressure, wear, and exposure to external agents.

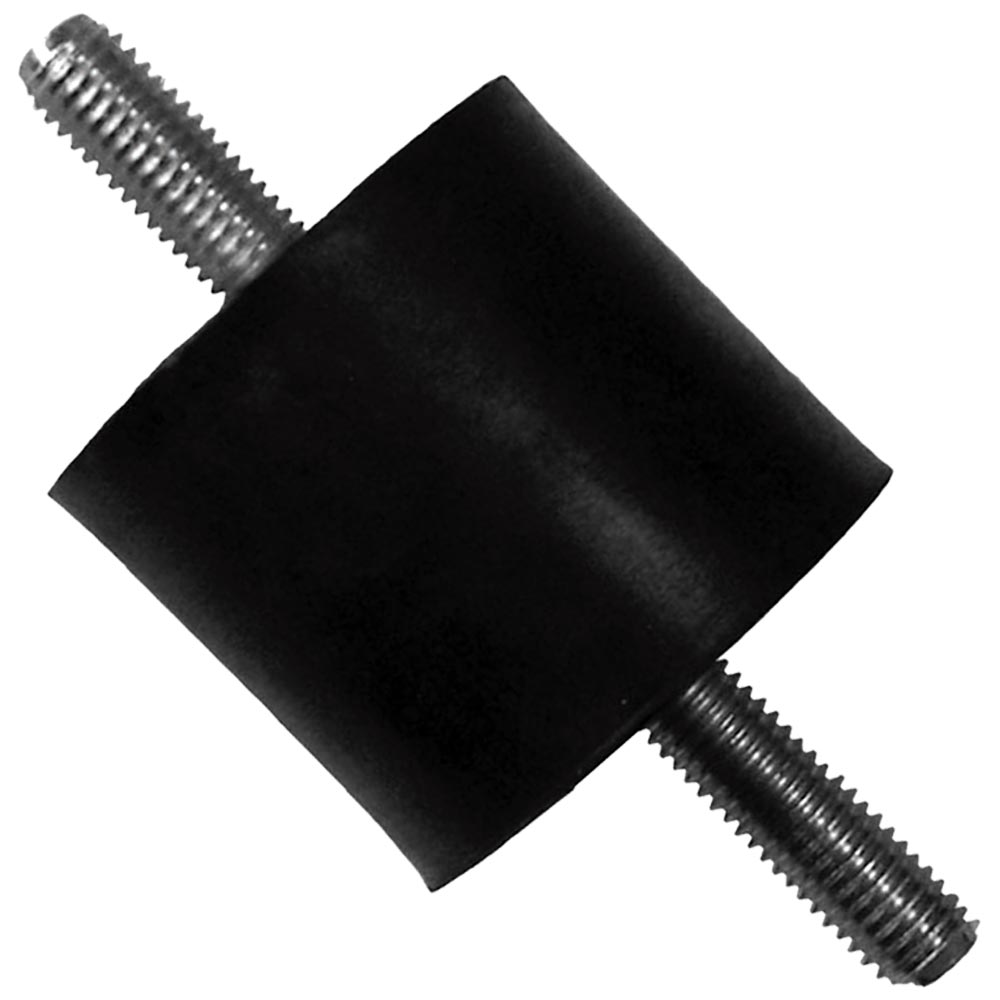

Mainly used for their high elasticity and excellent resistance to extreme temperatures and chemical agents, these products combine rubber’s mechanical properties with the structural benefits of metal inserts. Termogomma produces vibration dampers, elastic joints, supports, and antivibration bars used in naval, automotive, and heavy industrial systems. These rubber and metal components are especially effective in reducing noise, vibration and mechanical stress, offering long-term reliability even in harsh conditions. The internal expertise in bonding technologies ensures a strong and lasting connection between the rubber and the metal components.

The presence of fabric reinforcement within the rubber body ensures enhanced tear resistance, mechanical strength and long-term durability. These rubber and cloth products are essential in industrial applications where flexibility and robustness are required. Termogomma produces reinforced membranes, hoses, and transmission joints that are able to resist abrasion, corrosion, and pressure. These components are particularly suitable for use in ventilation, heating, and piping systems. The cloth insert offers a performance advantage in terms of strength and adaptability, making these components a trusted choice for both standard and custom configurations.

Design details

Termogomma manufactures rubber components based on the customer’s specifications. We ensure consistent quality, performance, and durability, each verified by our specialised team with expertise in both injection and compression moulding. We support our clients throughout every phase, offering guidance on the most suitable materials and contributing to the definition of the production process.