Designed for durability and precision, our engineered rubber rings are available in various shapes and sizes to meet the demands of agricultural machinery and ceramic processing systems.

What are high-performance rubber rings?

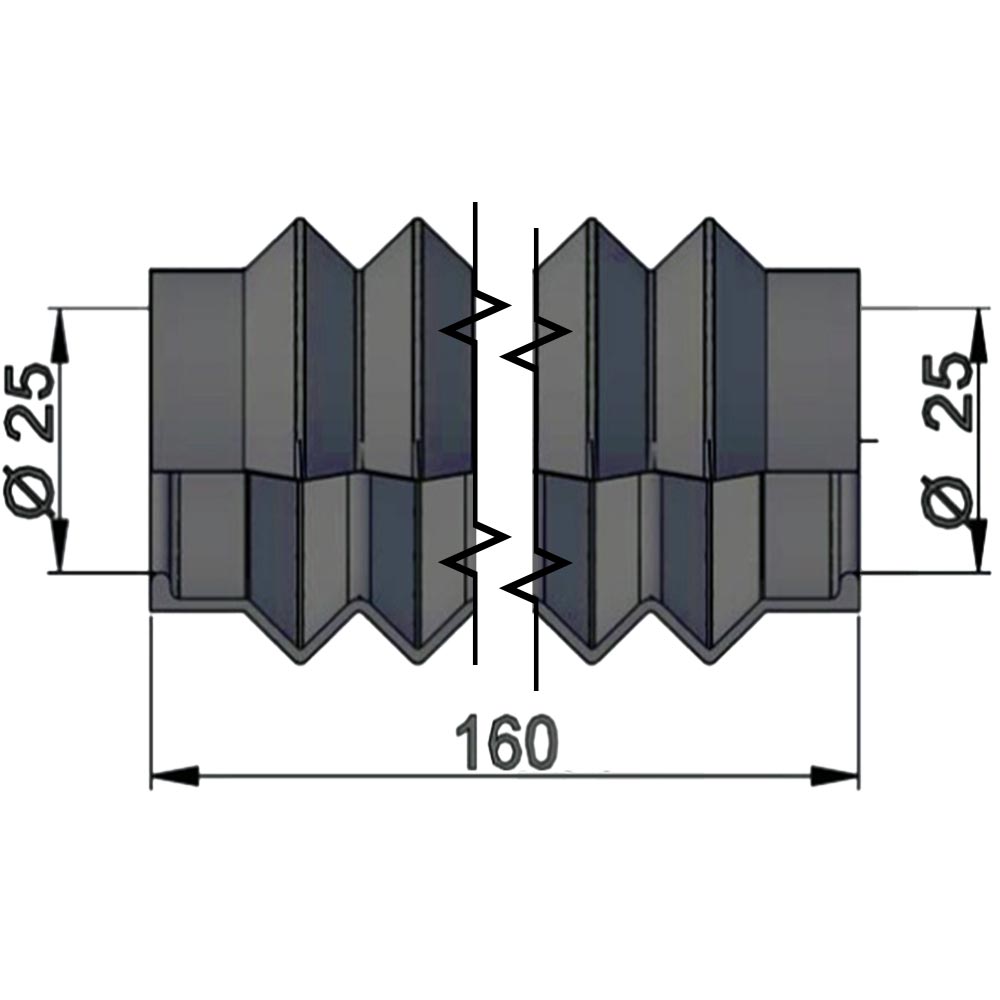

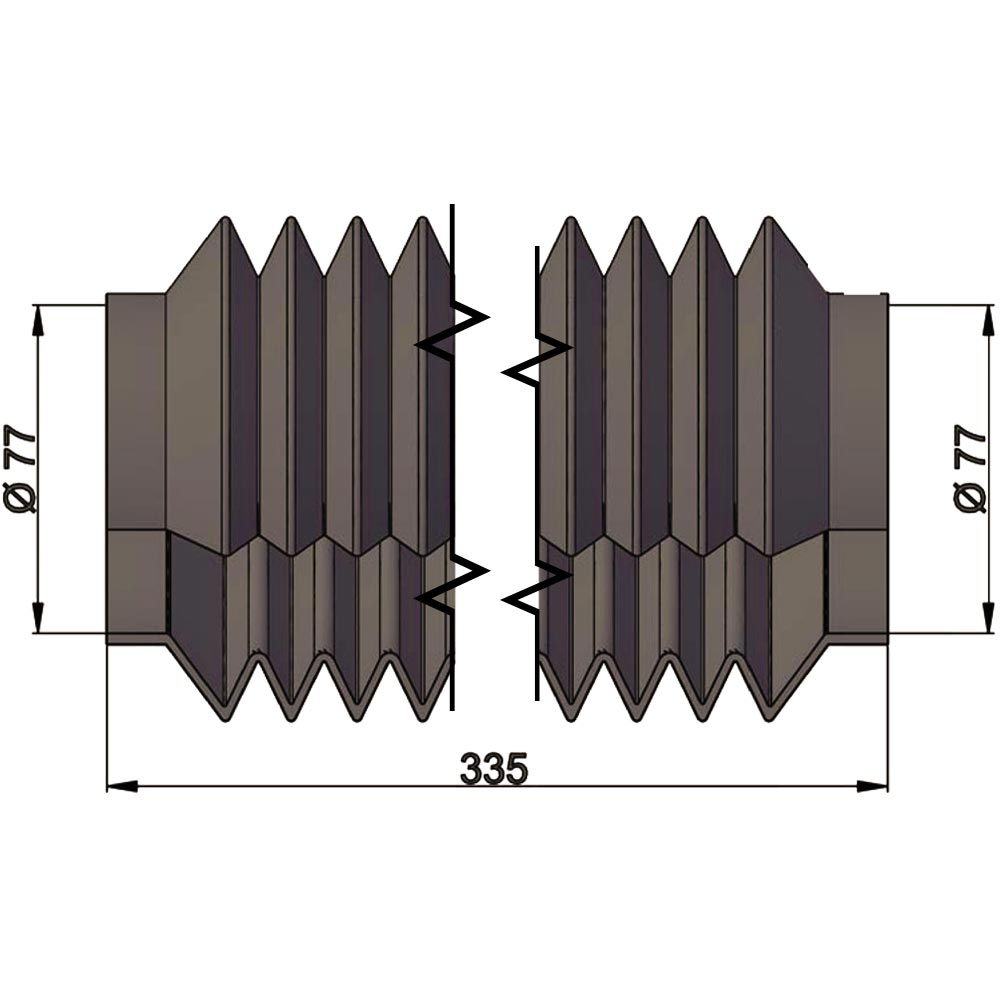

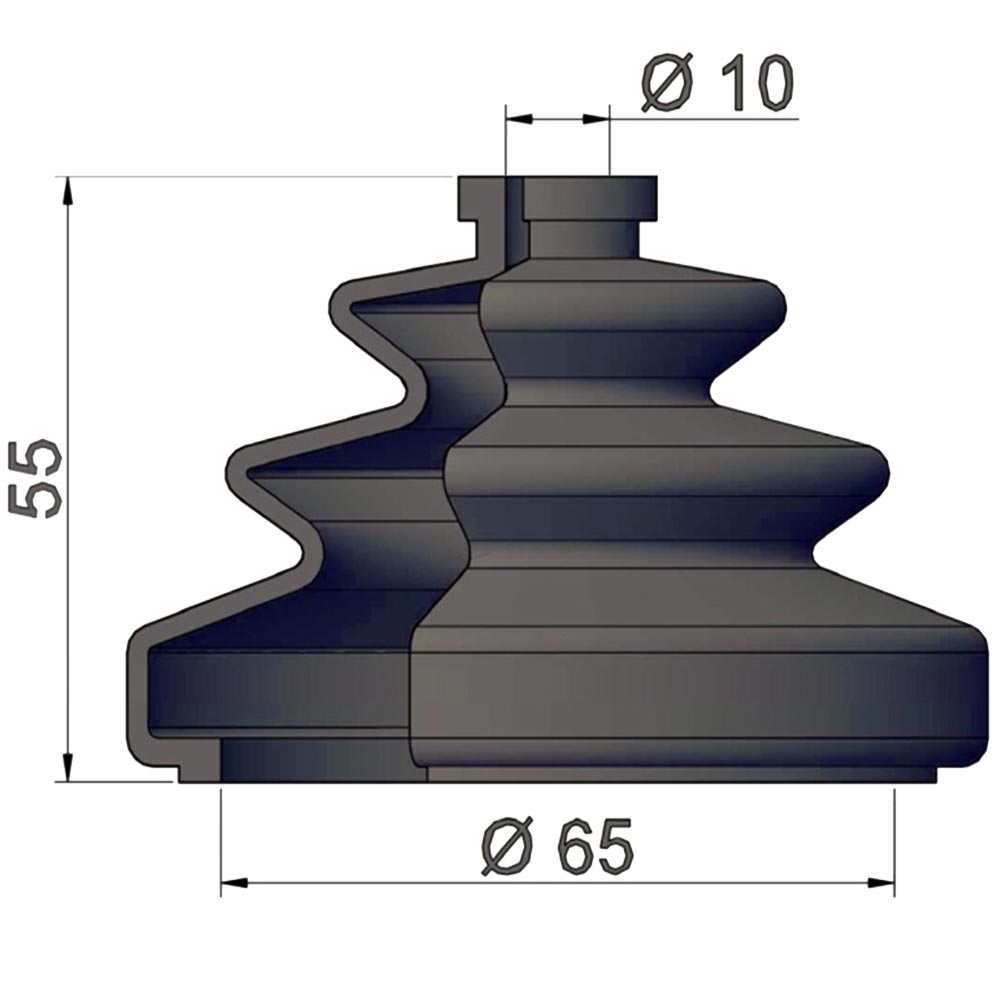

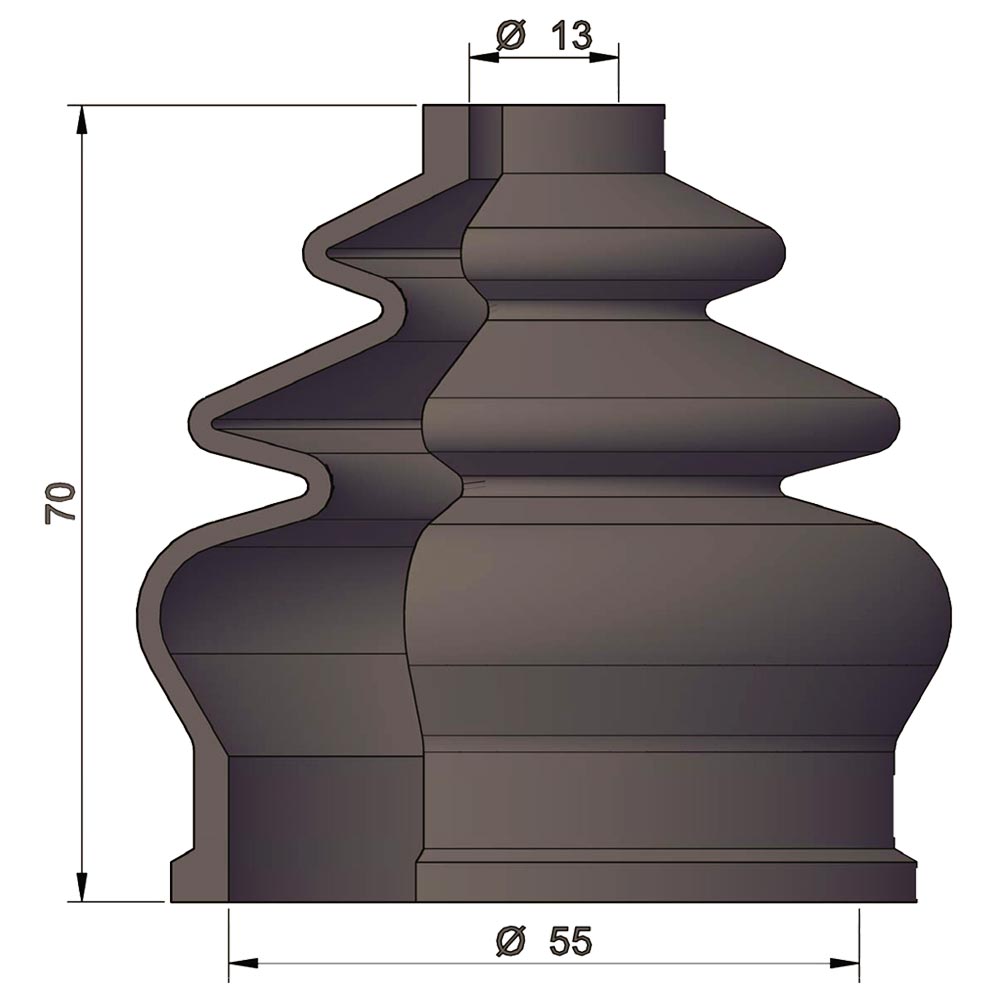

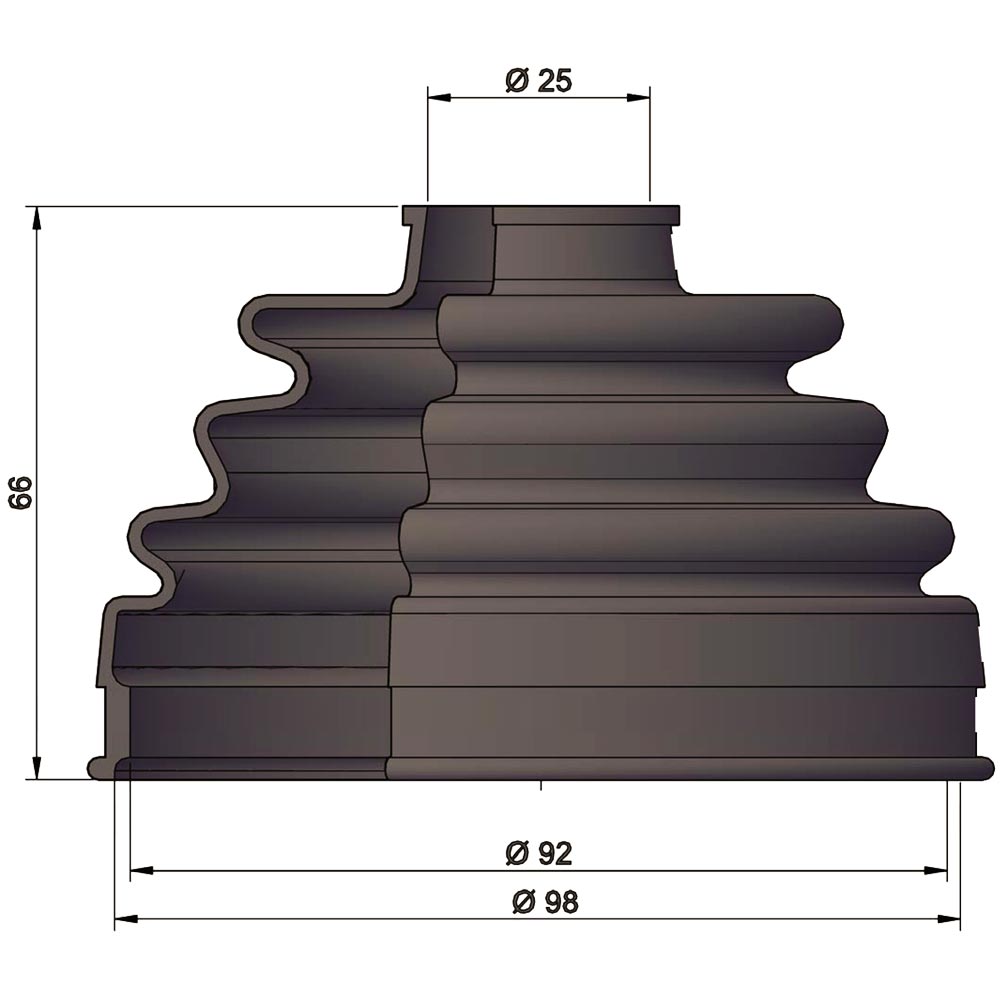

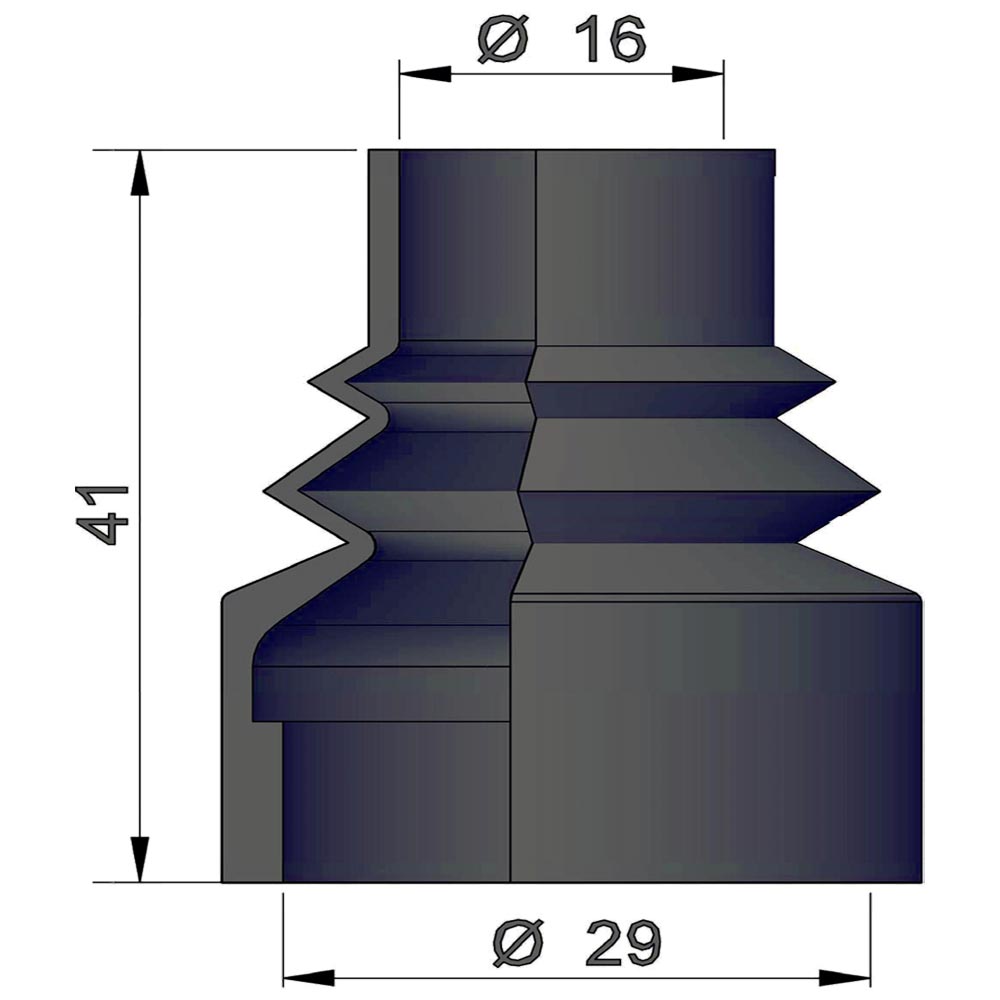

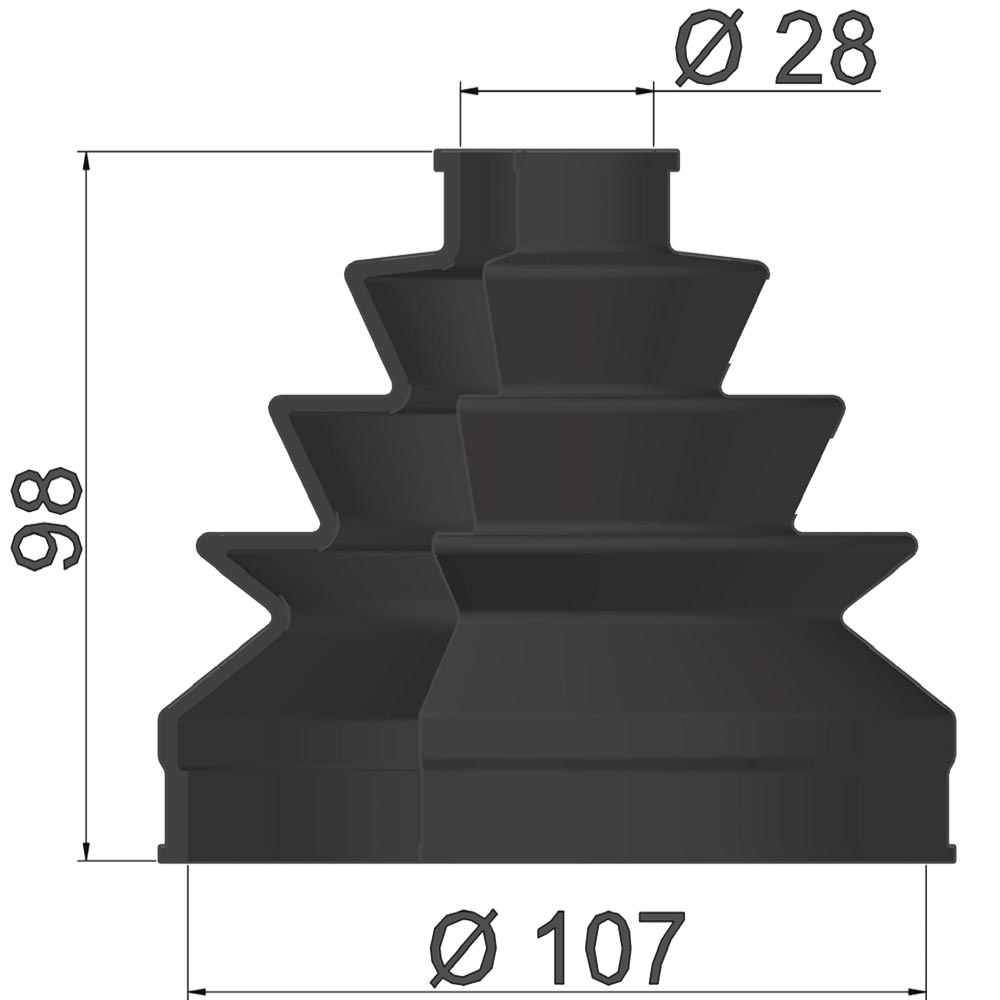

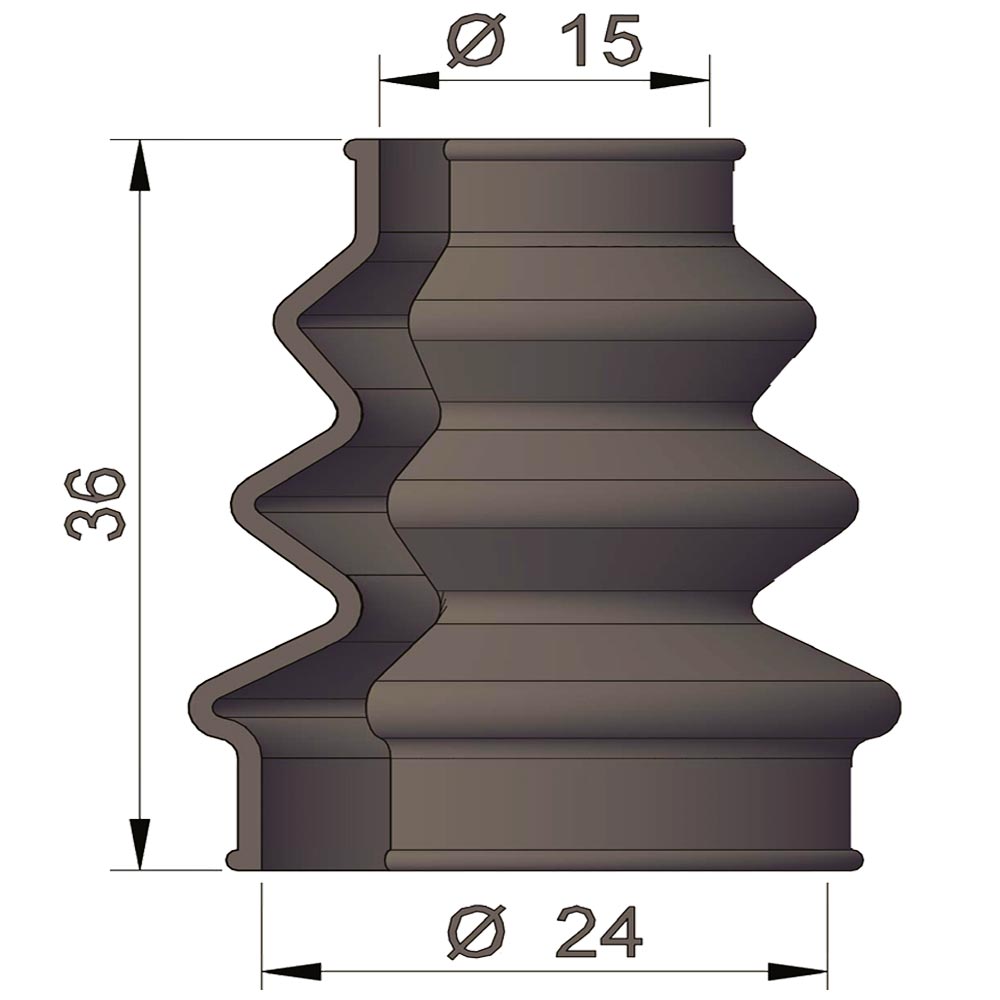

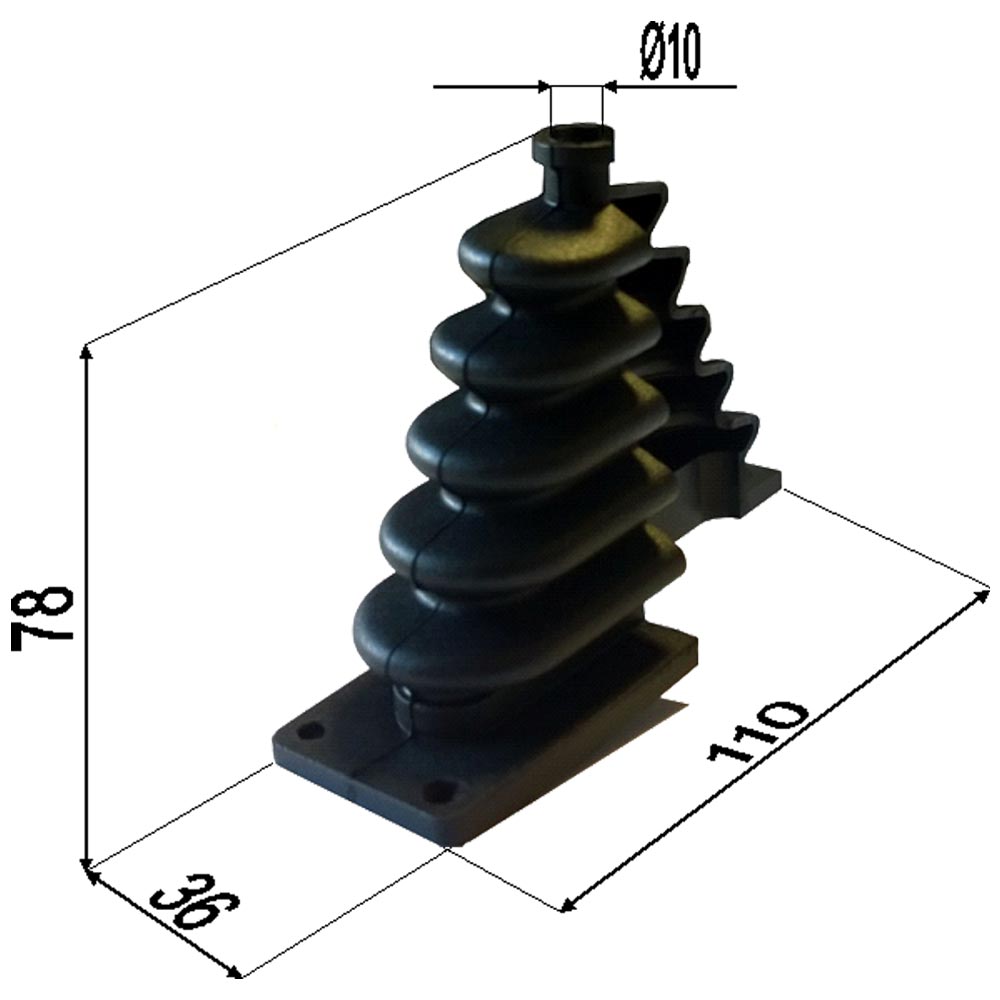

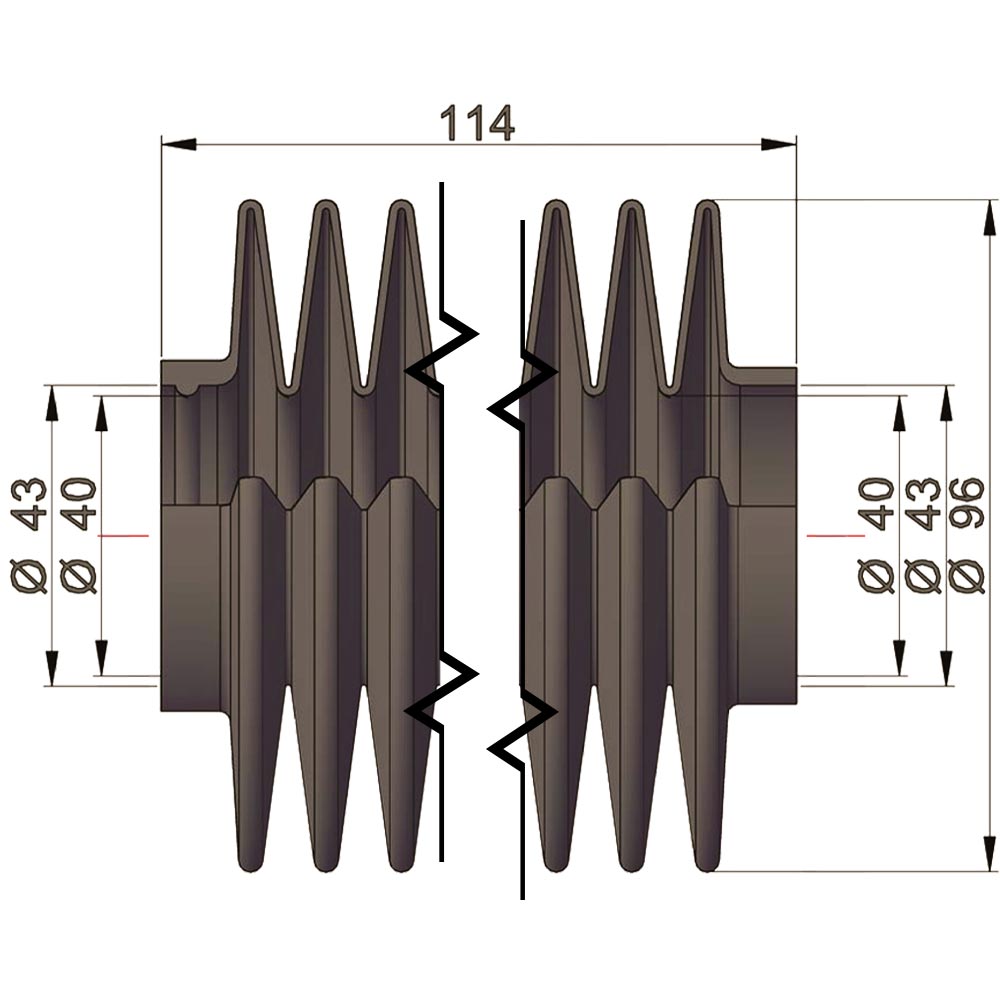

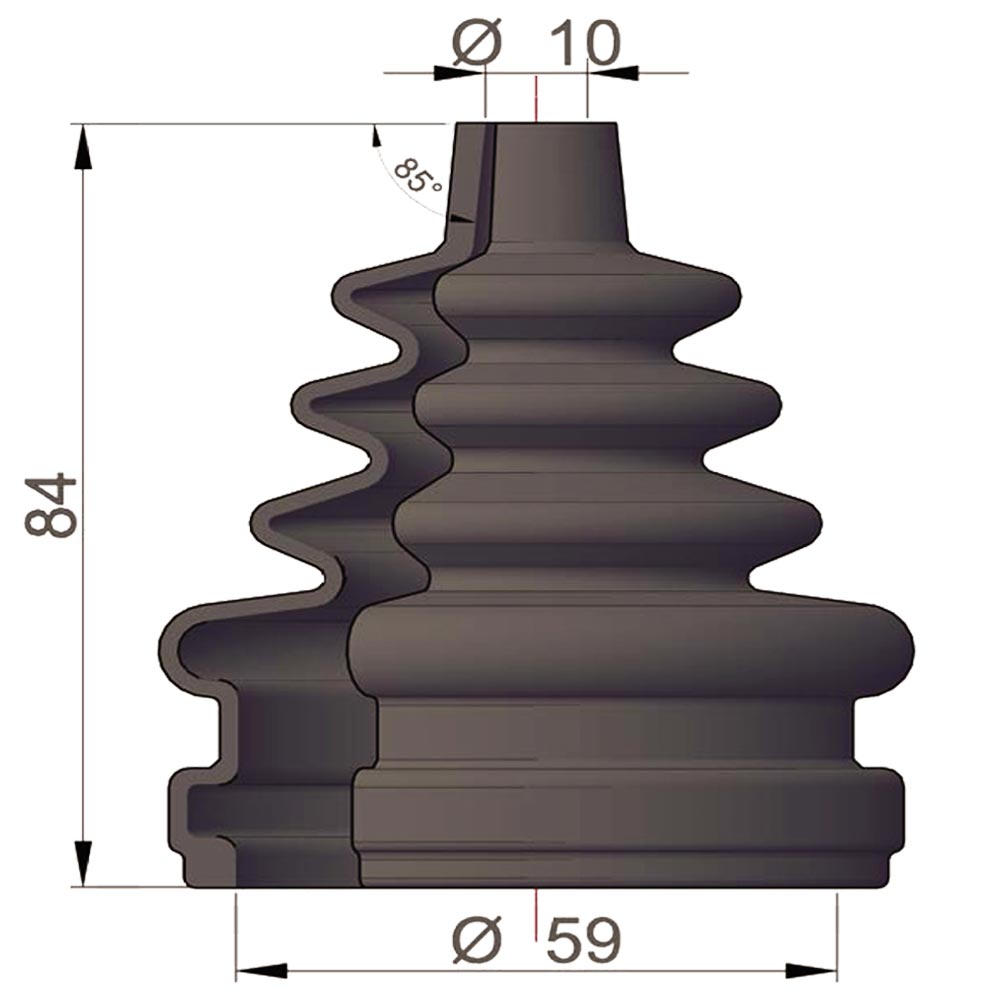

Rubber rings are functional elements designed to perform protective or finishing tasks within mechanical systems. Compact and highly resistant, they are ideal for rotary applications where durability, flexibility, and precise material behavior are essential. Thanks to their shape and tailored elastomer composition, they combine effective sealing, abrasion resistance, and mechanical support.

Termogomma manufactures these components with special rubber blends developed in-house to meet the demanding requirements of industrial applications.

Applications in agriculture and ceramic tile machinery

Rubber rings play a dual role in two highly specialized sectors.

- In ceramic processing systems, they are used in deburring units for glazed tiles, ensuring precise finishing and reducing mechanical stress on the tile edges. Their composition resists abrasion and maintains shape over repeated cycles.

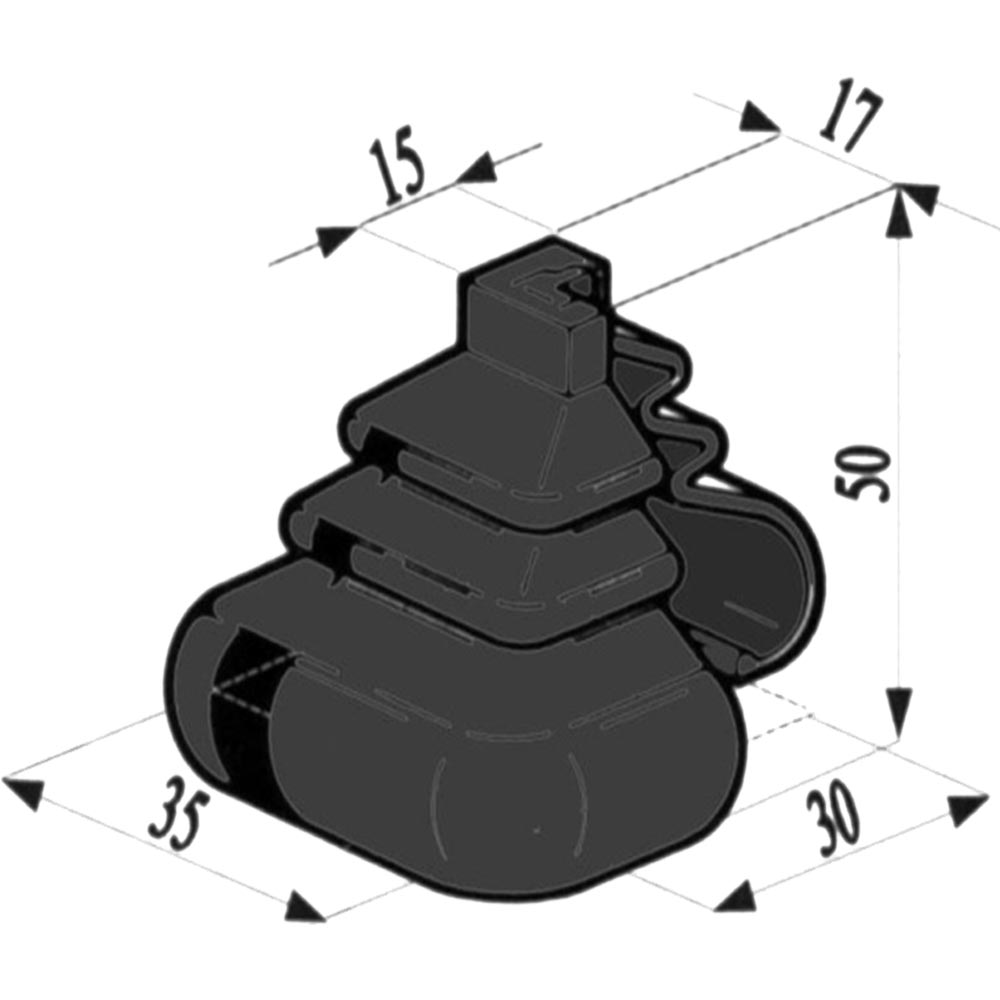

- In agricultural machinery, especially rotary equipment like mowers or trimmers, rubber rings are employed as protective elements to avoid damaging the bark of plants during cutting operations. Their flexibility allows them to absorb shock and adapt to irregular surfaces without compromising the crop.

Discover our sector-specific rubber components

Engineered materials for durability and flexibility

The rubber rings produced by Termogomma are made with high-performance compounds such as EPDM, NR, or custom-formulated elastomers that offer excellent resistance to wear, deformation, and environmental exposure. Each formulation is selected based on the working environment: exposure to chemicals, high rotational speeds, or outdoor conditions.

Our internal mixing and molding departments guarantee quality control and repeatability across all batches, whether for small quantities or large-scale production.

Technical development and in-house production

All components are developed based on customer specifications or derived from technical requirements in close cooperation with our R&D team. The process includes CAD design, prototyping, mold manufacturing, and pre-series validation. Dimensional precision and mechanical behavior are verified through internal testing protocols.

This approach ensures that each rubber ring fits seamlessly into its application, whether in dynamic machinery or abrasive environments.

A reliable partner for industry-specific rubber rings

With over five decades of experience in elastomer design and manufacturing, Termogomma provides tailor-made solutions for machinery in demanding industrial sectors. From tile finishing equipment to rotating agricultural tools, our rings are designed to last, perform, and protect.

The entrance in 2022 into ATP Group, a leader in sealing systems and plastic components, marked a phase of exponential growth for Termogomma. Both companies share the same commitment to innovation and quality in custom production for industrial applications.

Categorie

- Membrane11 product

- Reinforced joints11 product

- Rubber2727 products

- Rubber and cloth77 products

- Hoses55 products

- Rubber membrane11 product

- Rubber and metal1919 products

- Antivibration1414 products

- Elastic joints55 products