Designed for protection and flexibility, our high-performance components are available in multiple geometries and sizes for a wide range of industrial uses.

What are rubber bellows?

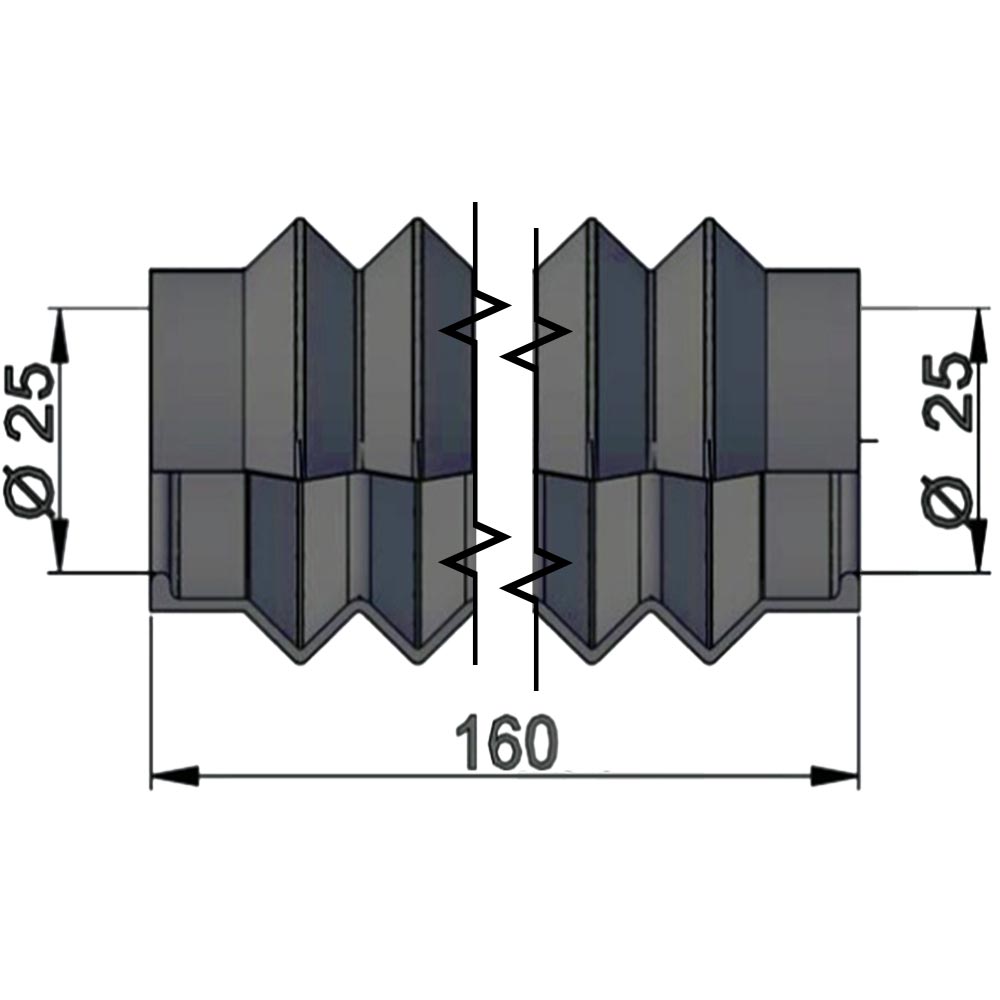

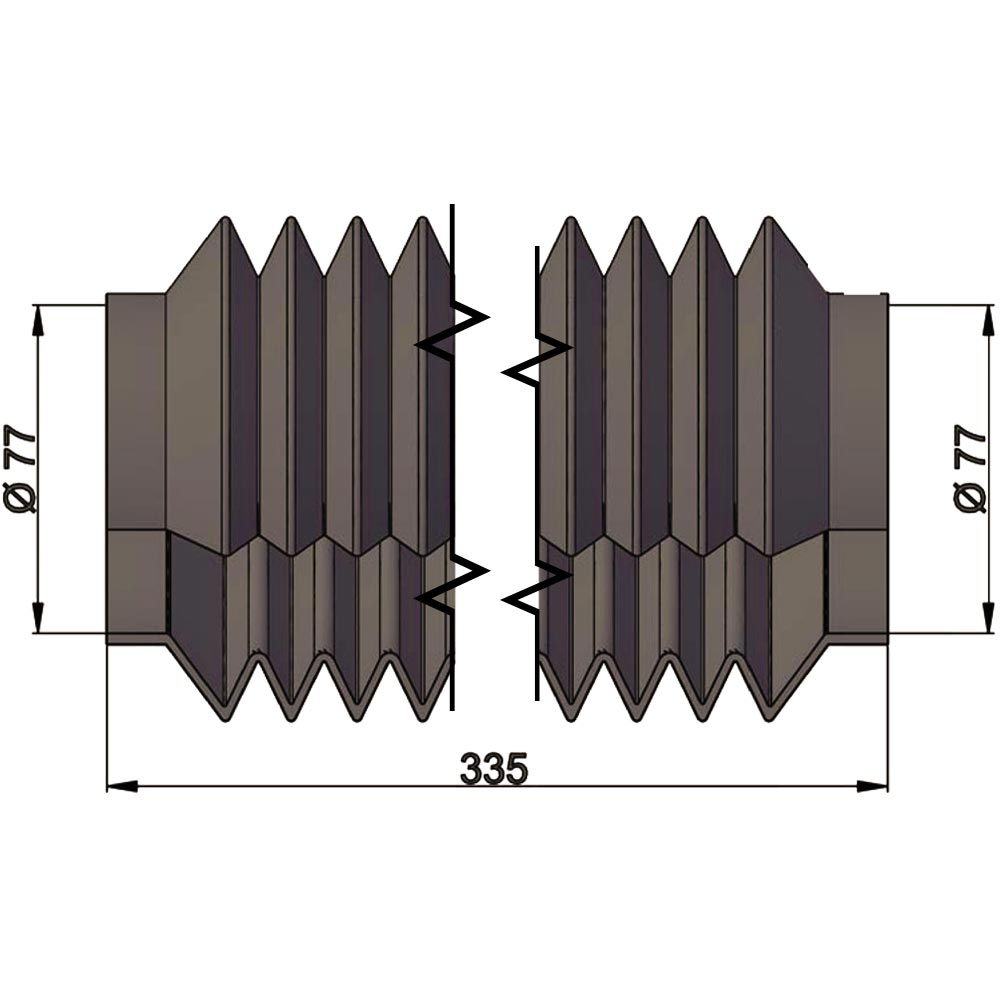

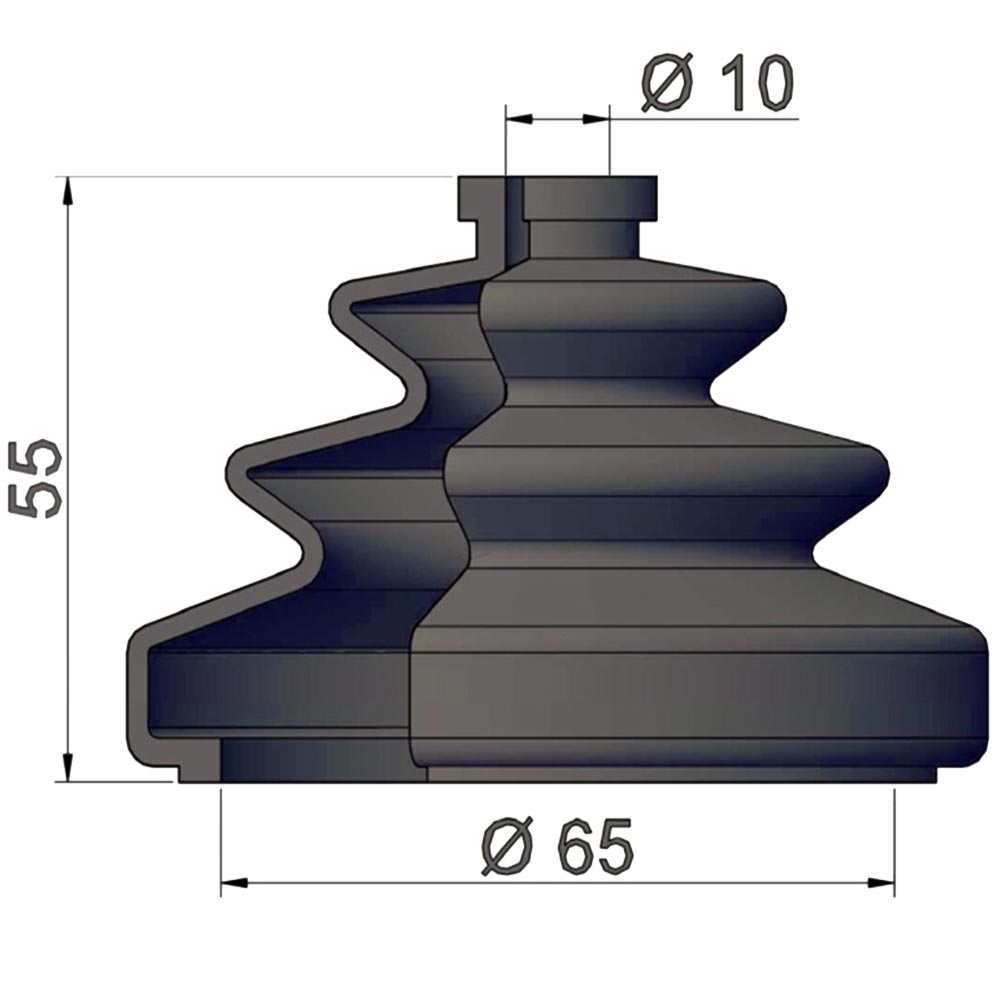

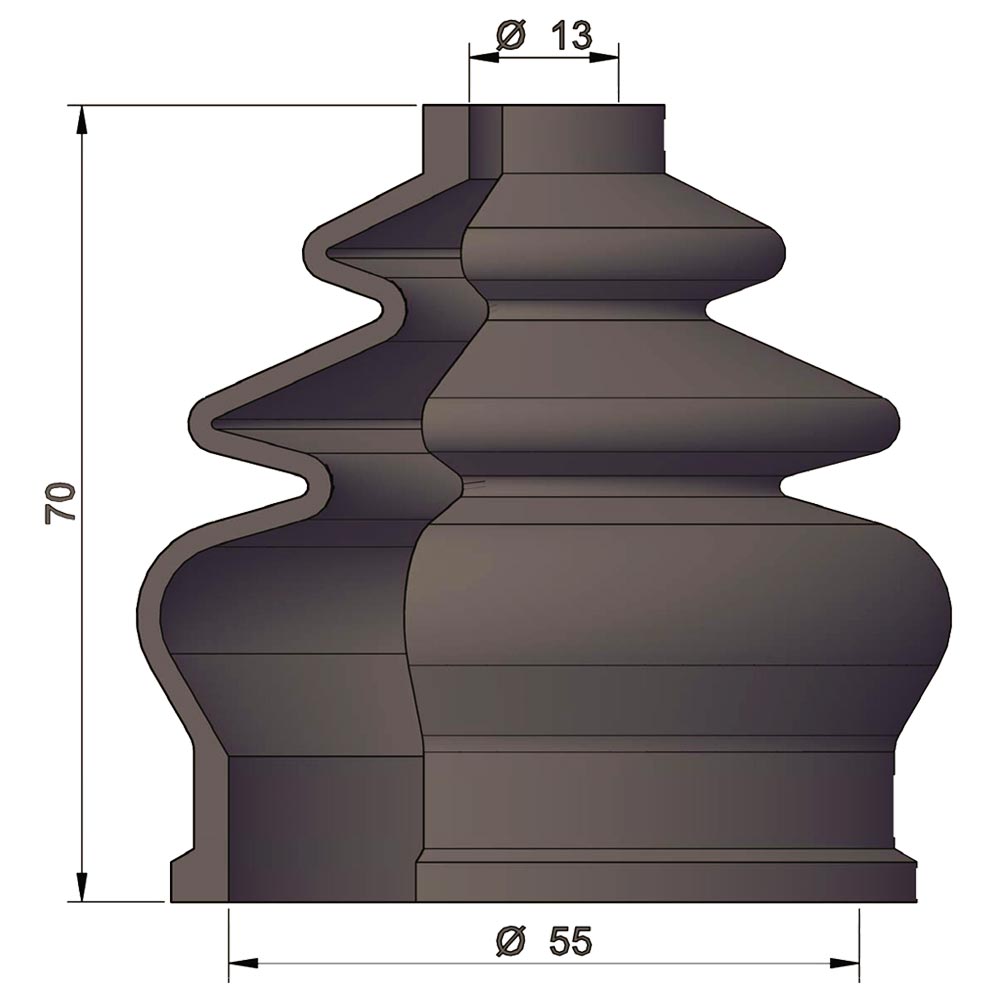

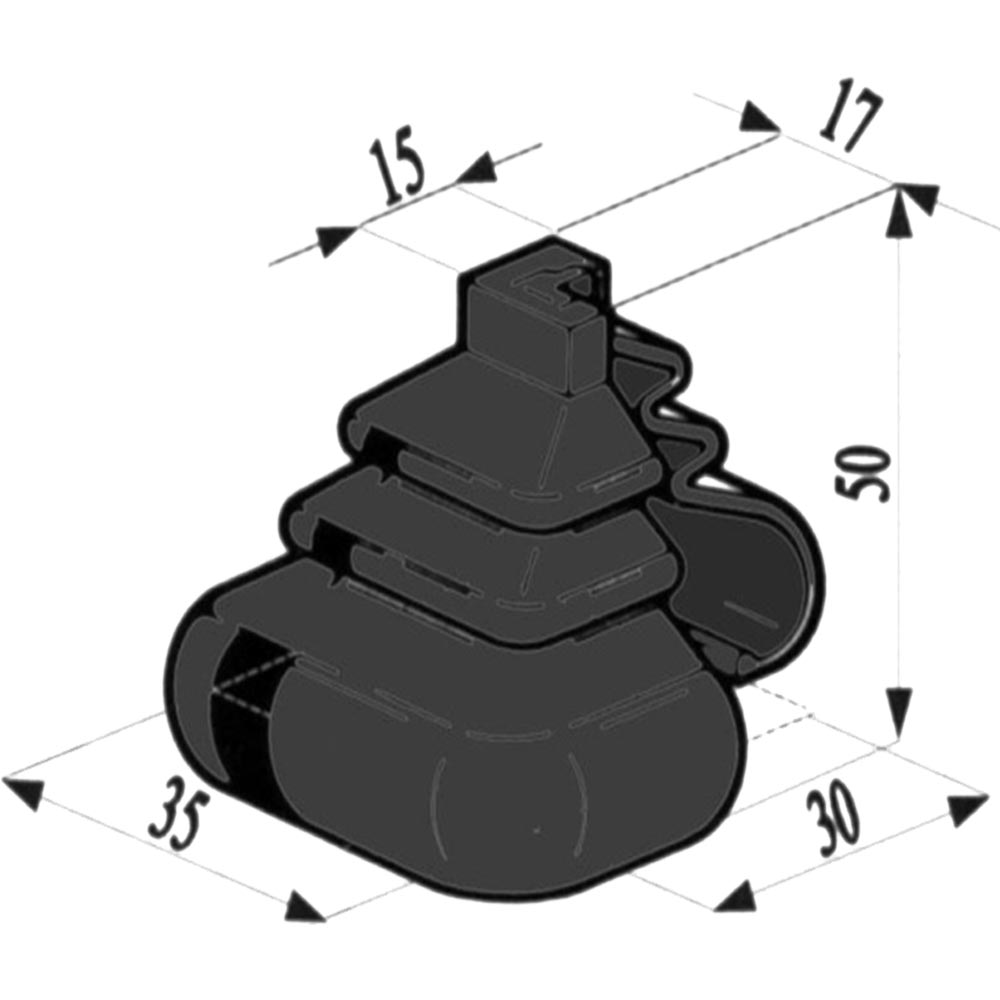

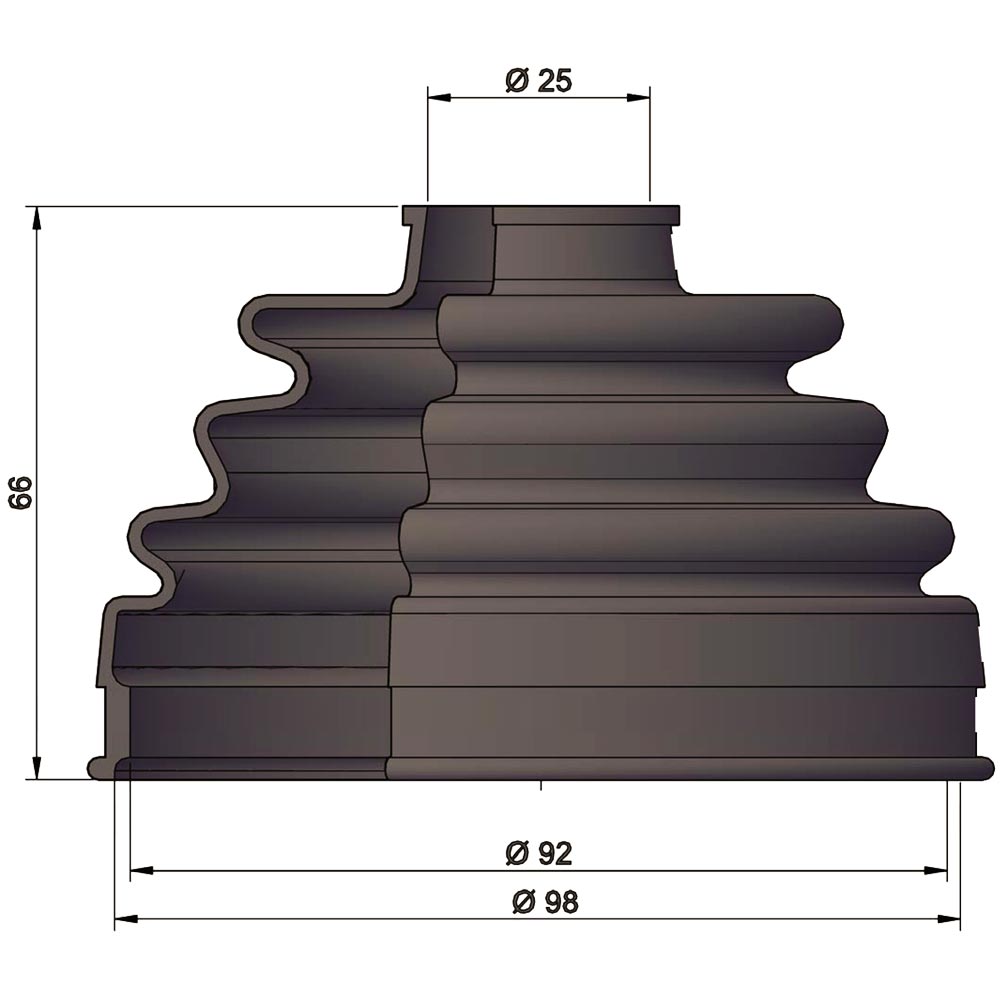

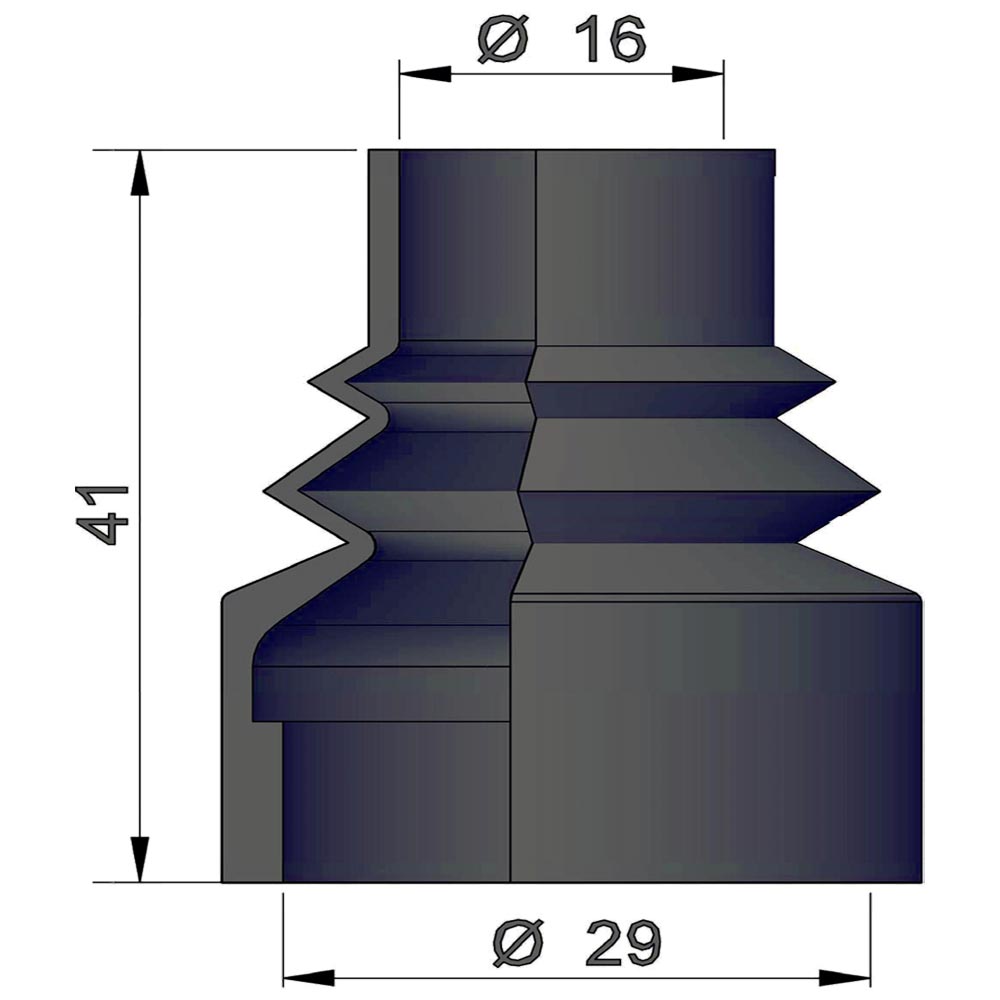

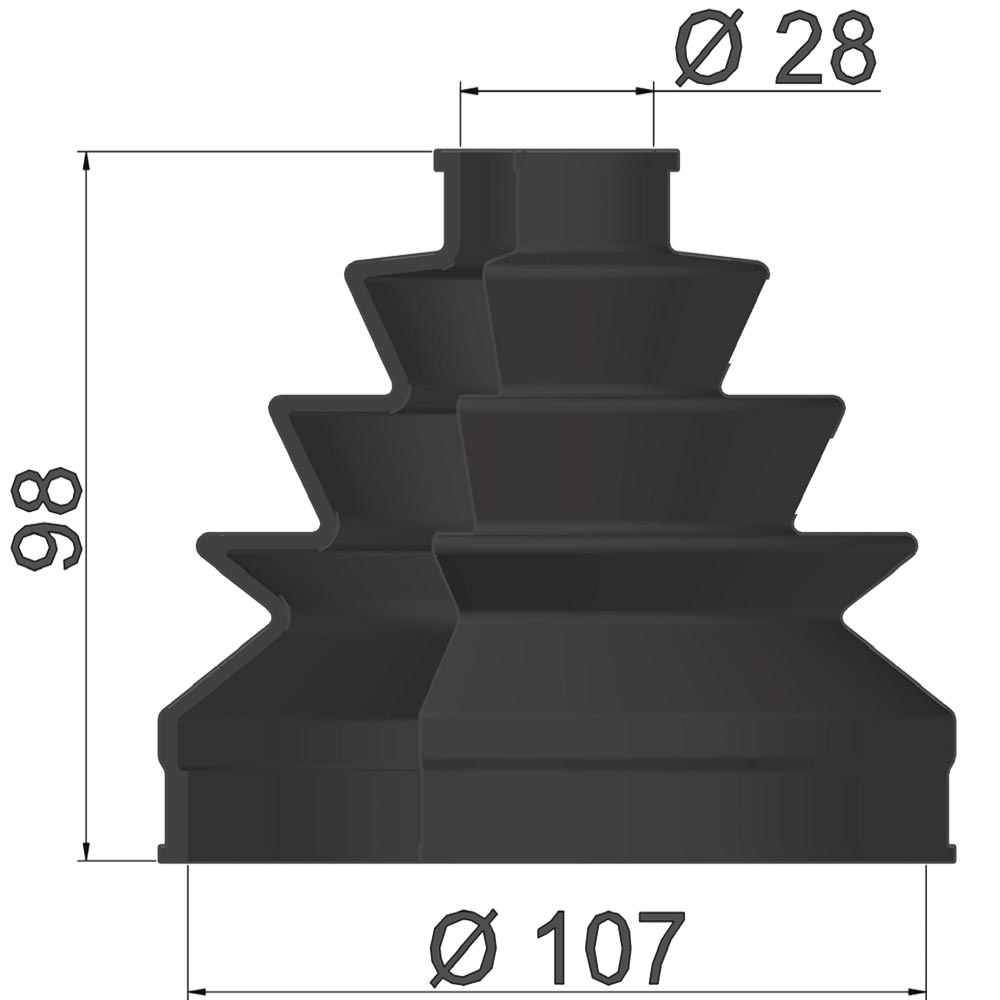

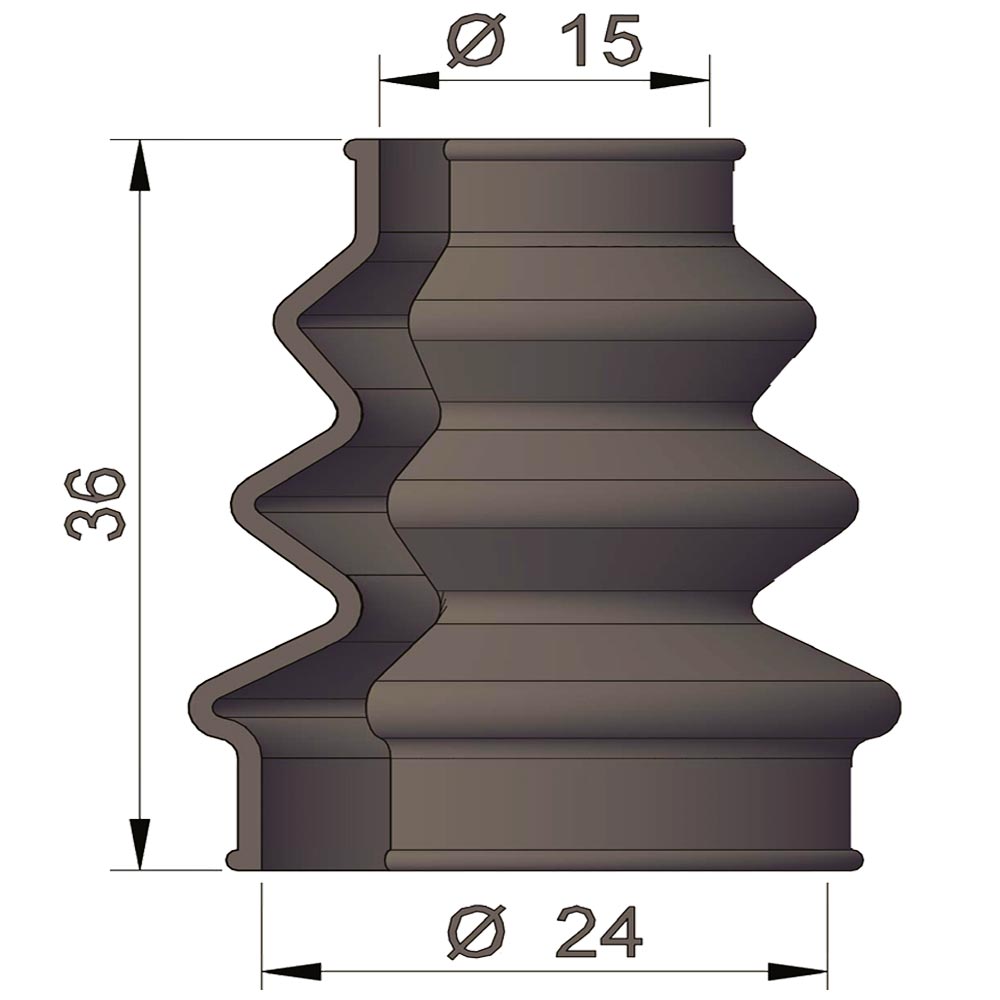

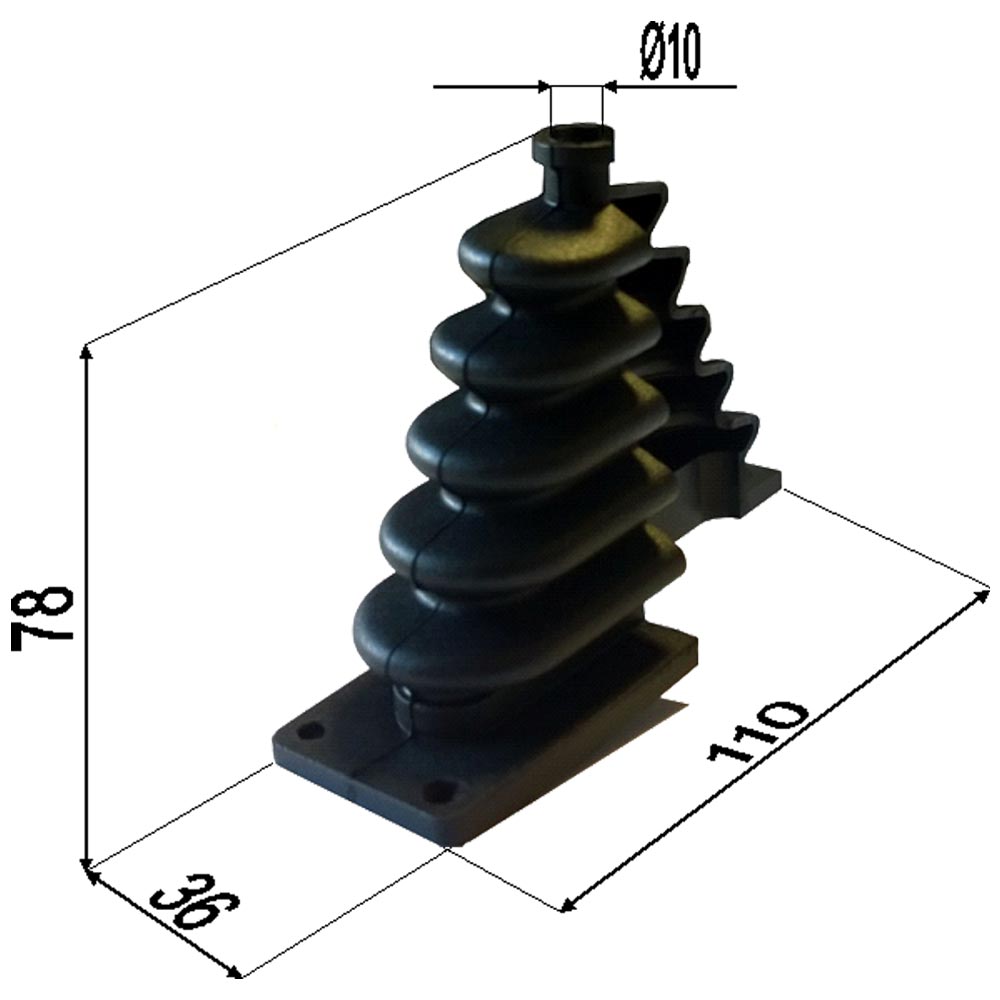

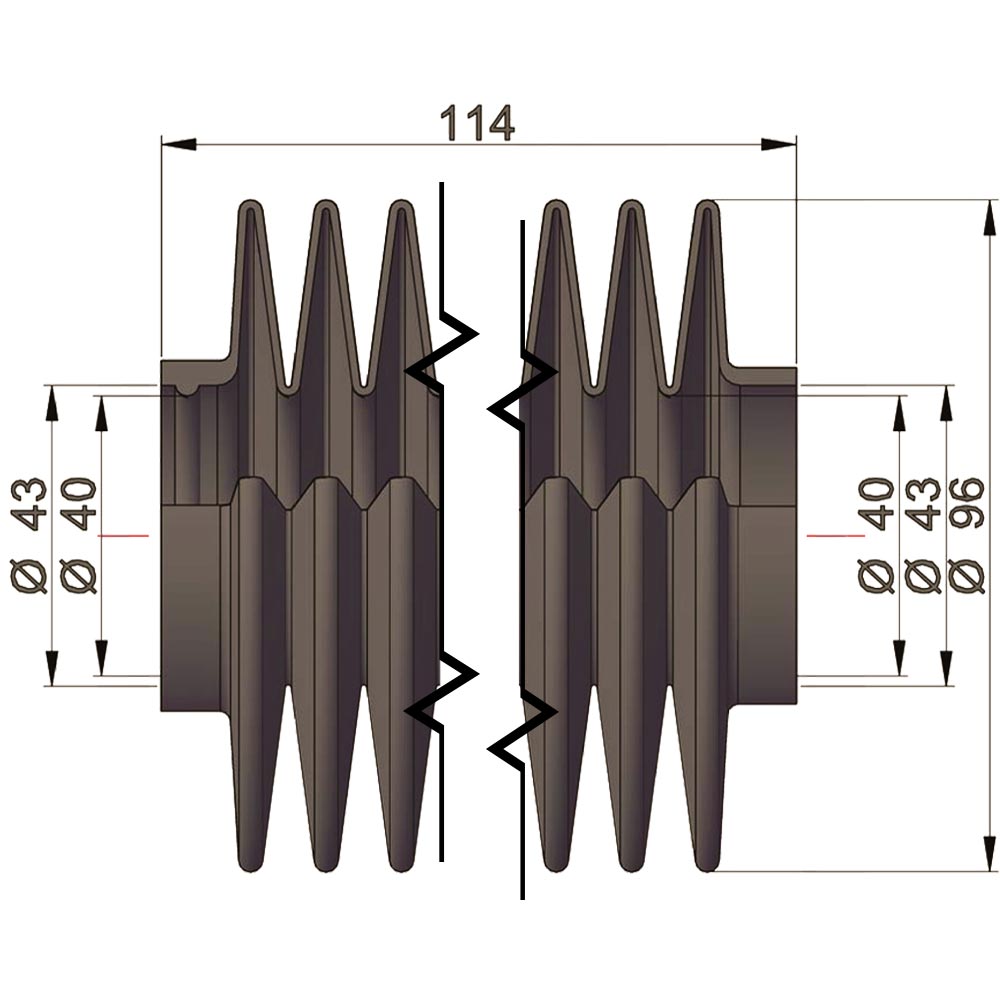

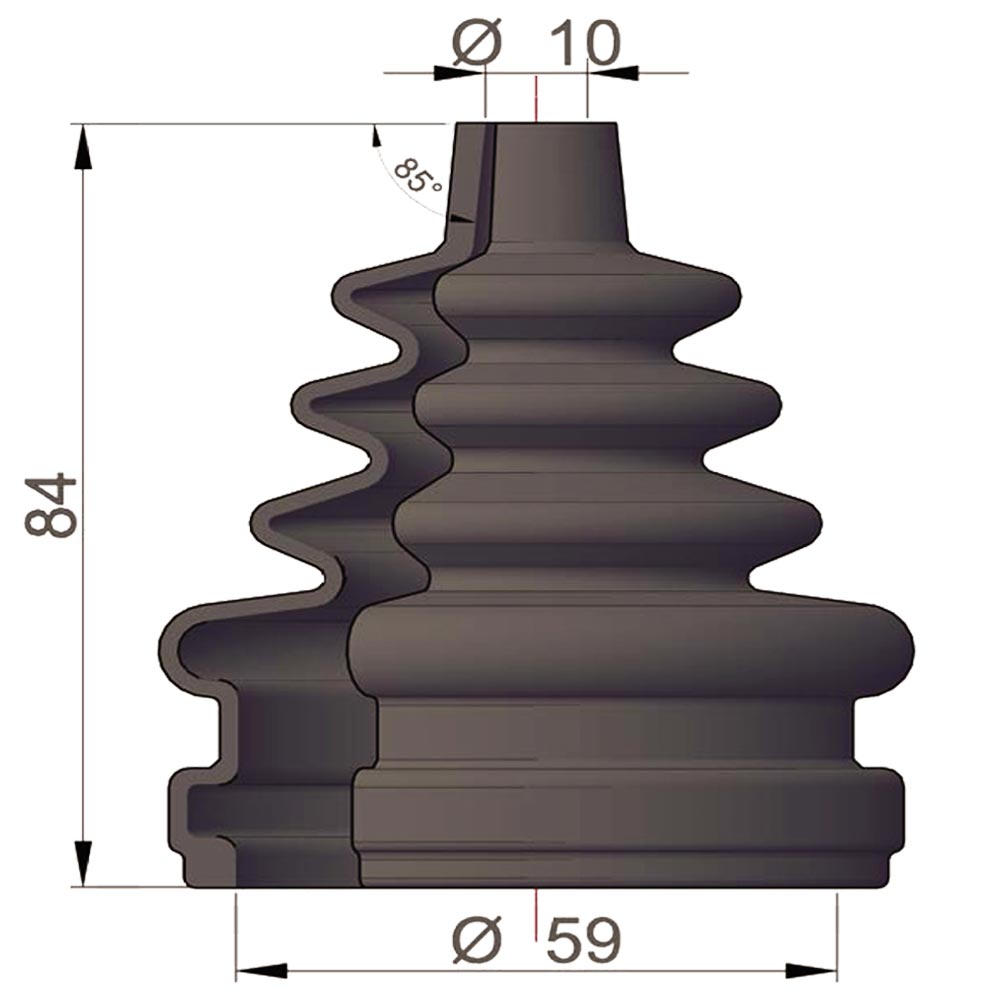

Rubber bellows are essential components used to protect moving mechanical parts such as joints, shafts, and actuators. These flexible elements shield sensitive parts from dust, liquids, and chemical agents, significantly extending the service life of machinery. Their structure allows them to absorb axial, angular, and lateral movements, ensuring reliable performance even in demanding environments.

Broad applications across industrial sectors

Rubber bellows are used in a wide range of industries, from automotive and agricultural machinery to robotics, medical devices, and food processing equipment. Each application comes with specific requirements, whether it’s mechanical strength, chemical resistance, or hygiene standards. We offer tailored solutions designed around the technical needs of each sector, delivering custom geometries and materials that match the working environment.

Discover our Food industry bellows.

Engineered materials for High Performance

To ensure top performance, our bellows are manufactured using carefully selected rubber compounds, including EPDM, NBR, silicone, and FKM. Each material is chosen based on the conditions it will face high temperatures, oil exposure, UV radiation, or chemical contact.

Discover our rubber products to explore the technical properties of each compound used in our production. Manufacturing processes include compression and injection moulding, with the possibility of integrating rigid inserts for easy assembly and improved structural integrity. Materials such as silicone and FKM are also suitable for use in applications requiring compliance with specific regulations.

Learn more about FDA rubber standards.

In-house design and quality control

All products at Termogomma are developed in-house, based on technical drawings, samples, or functional specifications. From prototyping to final production, every step is supported by strict quality control procedures that test durability, flexibility, and long-term resistance. This guarantees components that can withstand continuous cycles and challenging conditions without compromising performance.

A trusted Partner for custom elastomer components

With over 50 years of experience in rubber processing, Termogomma is a reliable partner for companies looking for high-quality, tailor-made elastomer components, even in small production runs. Each bellows solution is the result of a careful process that combines technical know-how, certified materials, and flexible manufacturing capabilities.

The entrance in 2022 into Atp Group, a leader in sealing systems and plastic components, marked a phase of exponential growth for Termogomma. Both companies share the same commitment to innovation and quality in custom production for industrial applications.

Discover our bellows in Atp Group

Categorie

- Membrane11 product

- Reinforced joints11 product

- Rubber2727 products

- Rubber and cloth77 products

- Hoses55 products

- Rubber membrane11 product

- Rubber and metal1919 products

- Antivibration1414 products

- Elastic joints55 products